Design and simulation of sheath flow system in liquid particle measurement

-

摘要:

液体颗粒测量技术是基于光散射法或光阻法,对液体中含有的颗粒物的粒径和数量等进行分析检测的技术。针对液体颗粒测量技术对测量精度的要求,基于流体动力聚焦原理,利用SolidWorks软件设计了用于液体中颗粒测量的鞘流系统模型。通过COMSOL的流体计算模块对该模型进行流体仿真计算,对聚焦流宽度的变化和系统对颗粒的聚焦性能进行仿真。仿真结果表明:该鞘流系统对样品流的聚焦性能与理论推导的一致,并且在样品流速度为0.1 m/s时,可将其聚焦到0.24 mm的宽度。并利用COMSOL颗粒追踪模块对该宽度下的颗粒轨迹进行仿真,实现了对颗粒的有效聚焦。在此基础上,对颗粒流经检测区时的状态进行分析,得出了重合误差的影响因素,对液体颗粒测量技术鞘流系统的实际设计具有一定的理论指导意义。

Abstract:Liquid particle measurement technology is based on light scattering method or photo resistance method to analyze and detect the particle size and quantity of the particles contained in the liquid. Aiming at requirements of the measurement accuracy of liquid particle measurement technology, based on the hydrodynamic focusing principle, the sheath flow system model for the measurement of particles in the liquid was designed by SolidWorks software. Through the fluid calculation module of COMSOL, the fluid simulation calculation of the model was carried out, and the change of the focusing flow width and the focusing performance of the system on the particles were simulated. The simulation results show that the focusing performance of the sheath flow system on the sample flow is consistent with the theoretical derivation, and it can be focused to 0.24 mm width when the sample flow speed is 0.1 m/s. Meanwhile, the COMSOL particle tracking module was used to simulate the particle trajectory at this width, and the effective focusing of particles was realized. On this basis, the state of particles flowing through the detection area was analyzed, and the influencing factors of coincidence errors were obtained, which had certain theoretical guiding significance for the practical design of the sheath flow system of liquid particle measurement technology.

-

引言

液体颗粒测量指对液体中存在颗粒物的数量、大小、浓度等参数进行测量。芯片行业中80%以上的工序都需要用水进行处理,水中含有菌落(1 μm~4 μm)或金属残留物会降低器件的性能,因此其生产时需要用粒径小于0.2 μm、浓度小于100个/ml[1]的超纯水。在军用领域,航空发动机中液压系统故障70%~80%是由液压油中的微米颗粒导致的[2]。在医药领域,药剂中直径大于毛细血管的颗粒(6 μm~8 μm)会对血管造成堵塞,产生不可挽回的影响[3]。因此,液体颗粒测量技术有广泛的应用前景。

目前颗粒测量技术主要采用光散射法和光阻法,颗粒是单个通过光敏区才能保证测量精度。2018年,刘东岳[4]设计了光散射式油液颗粒检测模块,分析了电路中的噪声,从信号处理的角度来提升测量准确度。2020年,陈明[5]设计了一套基于光阻法的液体颗粒计数系统,将光敏区设计为500 μm的尺寸来使颗粒尽可能单个通过光敏区,工作流量为12 mL/min~24 mL/min。2021年,ZHANG H[6]通过对光学结构和精密电路的优化和设计,研制出测量误差在5%以内的高精度煤尘检测传感器,为提升颗粒测量计数的准确度提供了思路。

在流式细胞术领域,通常采用鞘流技术来实现颗粒单个通过光敏区[7-8]。鞘流技术是基于流体动力聚焦原理,当内部的流体和外部的流体都为层流模式时,高速流动的外部流体在喷嘴处会挤压内部流体,且两者互不混合,在出口处内部的流体在外部的流体包裹下流出。通过改变外部流体的流速,可改变对内部流体的挤压程度,实现对内部流体宽度的控制[9-10]。当内部流体为含有待测颗粒的样品液时,外侧鞘液可将样品液的挤压形成一条宽度很窄的直线流,以达到待测样品液中的颗粒形成单列颗粒流的目的。

基于流体动力聚焦原理,设计了液体颗粒测量鞘流系统模型,由鞘管、样品管和喷嘴、出口管组成。然后利用COMSOL对其进行仿真,验证了其对样品流的聚焦性能,并和理论推导结果进行比较分析;对颗粒在流动过程中的受力过程进行分析,并对颗粒轨迹进行仿真,验证了分析的准确性。最后,对颗粒测量技术中由于颗粒同时经过光敏区而产生的重合误差的影响因素做了研究。

1 基本原理

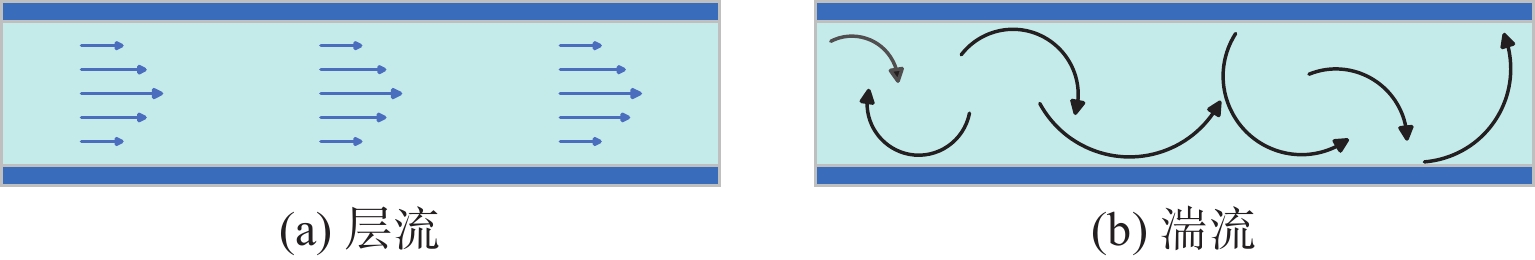

流体动力聚焦是鞘流系统的主要原理,流体根据流动状态主要分为层流和湍流,如图1所示。层流是一种流体流动的稳定状态,惯性力占主导作用,其特点是流线平行。而湍流是一种流体流动的不稳定状态,各流层之间会发生混合流动,流线紊乱[11-12]。

样品颗粒是沿着聚焦的样本流行进,为了使其聚焦后做稳定的直线运动,就需要所在流体是层流状态。在流体力学中,雷诺数Re是判断流体流态的依据,是一个与黏性力和惯性力之比有关的无量纲参数,通常用符号Re表示[13],其计算公式为

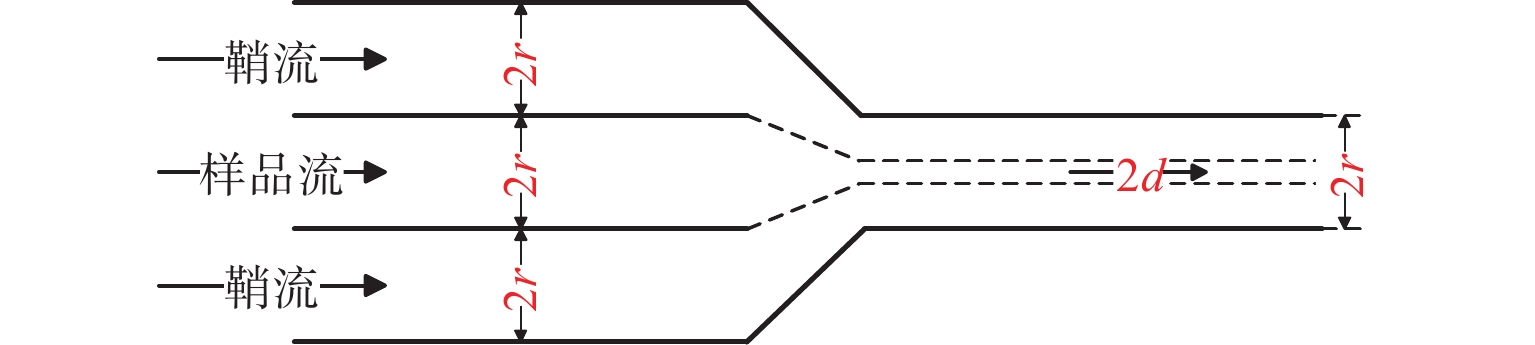

$$ Re = \frac{{\rho vd}}{\mu } $$ (1) 式中:$\rho $为流体密度;$\mu $为流体动力黏性系数;v为流体流动的平均速度;$d$是通道的水力直径。当Re的值小于2 300时,流体的状态为层流;当Re的值大于4 000时,流体的状态为湍流。如图2所示为鞘流技术中的流体动力聚焦。

样品液是从半径为r的圆管入口处流入,经两侧鞘液的挤压形成宽度为2d的聚焦流,由质量守恒定律可得出:

$$ \rho {r^{\text{2}}}{v_{\mathrm{b}}} = \rho {d^{\text{2}}}{v_{\mathrm{d}}} $$ (2) 式中:r、${v_{\mathrm{b}}}$为入口圆管半径与入口速度;$d$、${v_{\mathrm{d}}}$为聚焦后样品液的半径与速度。在整个鞘流系统内,由质量守恒定律可得出:

$$ {\rho _{\mathrm{b}}}{v_{\mathrm{b}}}{r^2} + {\text{4}}{\rho _{\mathrm{a}}}{v_{\mathrm{a}}}{r^2} = {\rho _{\mathrm{c}}}{v_{\mathrm{c}}}{r^2} $$ (3) 式中:${\rho _{\mathrm{a}}}$,${\rho _{\mathrm{b}}}$,${\rho _{\mathrm{c}}}$分别为鞘流、样品液、出口处混合液的密度;${v_{\mathrm{a}}}$,${v_{\mathrm{b}}}$,${v_{\mathrm{c}}}$分别是鞘流入口、样品流入口、混合流出口平均速度;r是每个口的半径。通道出口处流体处于层流状态时,其流速剖面成拋物线分布,则有:

$$ {v_{\mathrm{d}}} = {v_{\max }} = 1.5{v_{\mathrm{c}}} $$ (4) 式中${v_{\mathrm{d}}}$为聚焦后样品流的速度,从而通过推导可得出流体聚焦后的半宽度d:

$$ d = 2r\sqrt {\frac{{{\rho _{\mathrm{c}}}}}{{{\rho _{\mathrm{b}}} + {\text{4}}{\rho _{\mathrm{a}}}\times \dfrac{{{v_{\mathrm{a}}}}}{{{v_{\mathrm{b}}}}}}}} $$ (5) 样品流的聚焦流半宽度$d$与鞘流与样品流速度的比值${{{v_{\mathrm{a}}}} \mathord{\left/ {\vphantom {{{v_a}} {{v_b}}}} \right. } {{v_{\mathrm{b}}}}}$成反比。在样品流和鞘层流体互不相溶的情况下,混合流体的密度${\rho _{\mathrm{c}}}$可计算为

$$ {\rho _{\mathrm{c}}} = \frac{{{{{M}}_{{\mathrm{out}}}}}}{{{{{V}}_{{\mathrm{out}}}}}}{\text{ = }}\frac{{{r^2}{\rho _{\mathrm{a}}} + {d^2}({\rho _{\mathrm{b}}} - {\rho _{\mathrm{a}}})}}{{{r^2}}} $$ (6) 式中:${M_{{\mathrm{out}}}}$为出口管内流体质量;${V_{{\mathrm{out}}}}$为出口管体积。

2 鞘流系统仿真分析

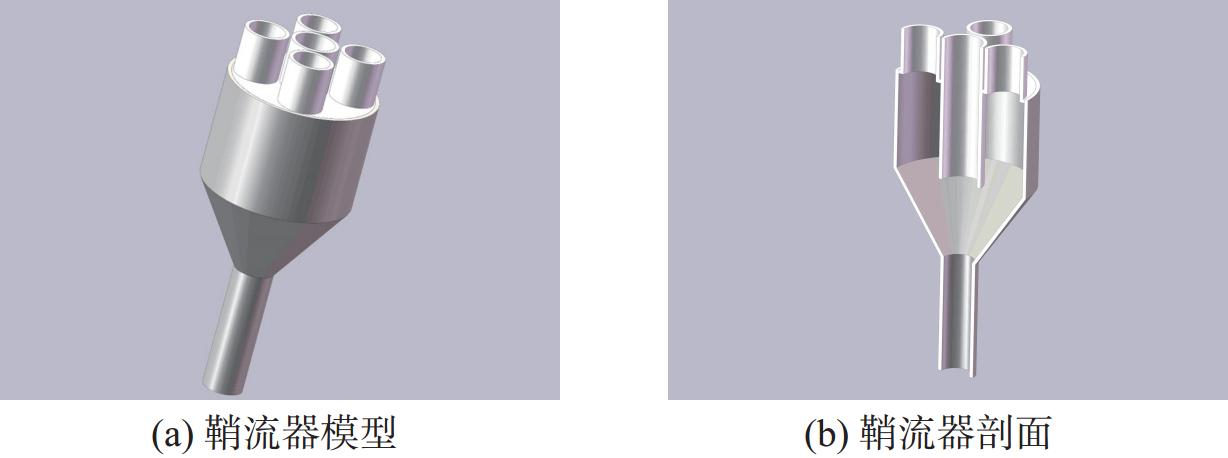

2.1 鞘流系统的结构

利用SolidWorks软件设计的鞘流系统模型如图3所示。鞘液入口采用4侧,使得样品流可以更好地聚焦在中心位置,鞘液管、样品管、喷嘴处的出口管直径均为2 mm。

仿真条件设置如下:鞘液为纯水,动力黏度为0.001 Pa·S,密度为1 000 kg/m3;样品液为橄榄油,动力黏度为0.1 Pa·S,密度为900 kg/m3;大气压为101 325 Pa;温度为293.2 K。

2.2 鞘流系统性能仿真

在进行仿真时,壁条件选择无滑移壁,入口边界条件选择“充分发展的流动−平均速度”,出口边界条件选择“充分发展的流动−平均压力”。聚焦流的宽度由样品流速度与鞘层流体流速之比来改变,将式(5)代入式(4),并将仿真边界条件及流体数据代入:

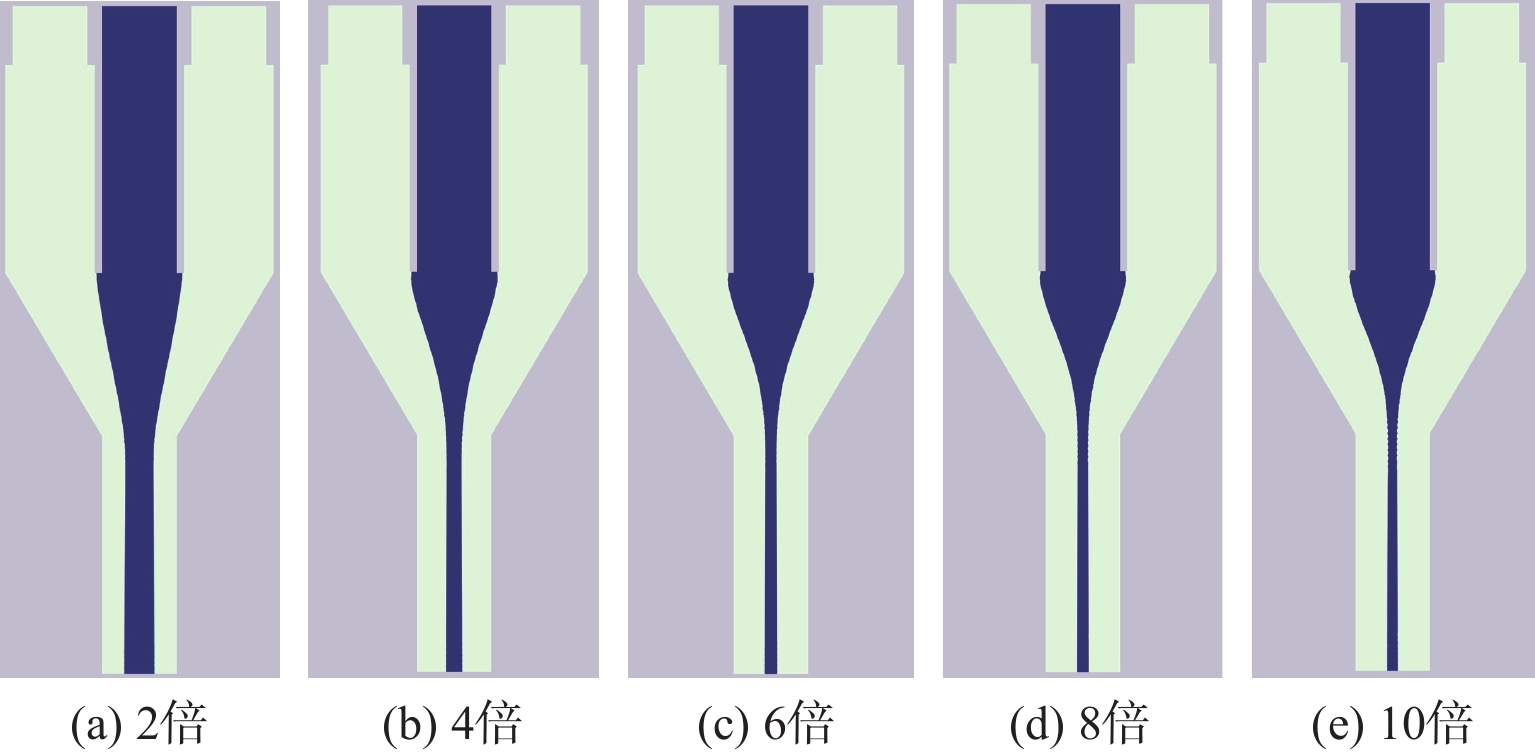

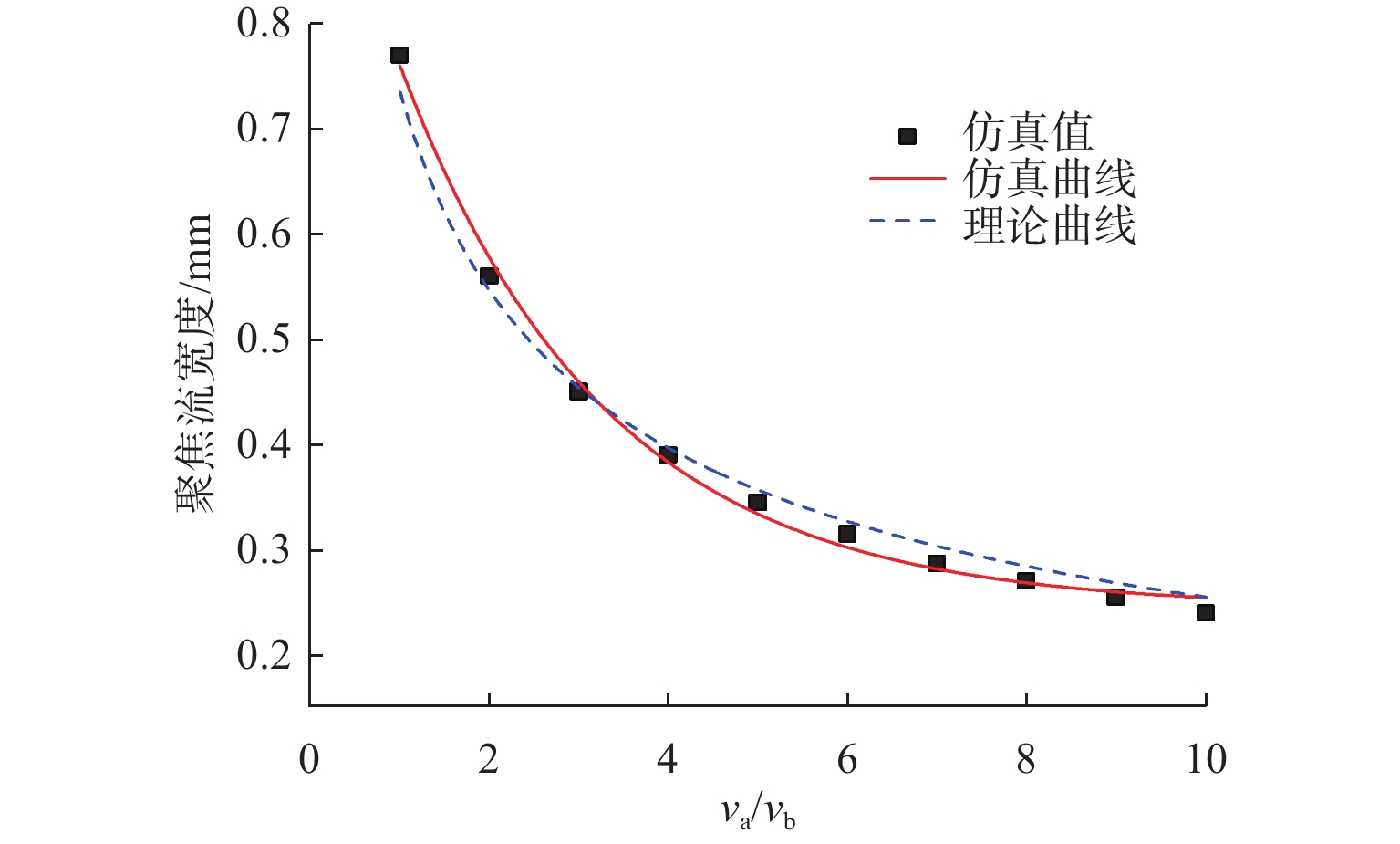

$$ d=\sqrt{\frac{\text{1}-\text{200}{d}^{2}}{\text{1}\text{.5}\times \left(\text{800}+4\times \text{1 000}\times \dfrac{{v}_{{\mathrm{a}}}}{{v}_{{\mathrm{b}}}}\right)}} $$ (7) 将样品流入口速度固定在0.1 m/s,流量约为20 ml/min,鞘流与样品流的流速比${{{v_{\mathrm{a}}}} \mathord{\left/ {\vphantom {{{v_a}} {{v_b}}}} \right. } {{v_{\mathrm{b}}}}}$取1~10。仿真结果如图4所示。

图4中,聚焦流的宽度随鞘层流体流速与样品流流速之比而改变。当${{{v_{\mathrm{a}}}} \mathord{\left/ {\vphantom {{{v_a}} {{v_b}}}} \right. } {{v_{\mathrm{b}}}}}$分别为2,4,6,8,10时,样品流宽度分别为0.56 mm,0.39 mm,0.31 mm,0.27 mm, 0.24 mm。因此,可以通过样品流速与鞘层流体流速的比值来控制聚焦流的宽度,图5为${{{v_{\mathrm{a}}}} \mathord{\left/ {\vphantom {{{v_a}} {{v_b}}}} \right. } {{v_{\mathrm{b}}}}}$为1~10过程中由式(7)计算出的和仿真得出的聚焦流宽度变化曲线。

3 流体对颗粒的聚焦作用

3.1 颗粒在流动流体中的受力情况

仿真中设置的颗粒尺寸为1 μm,其在样品流中所受的力主要为重力Fg和曳力F,其中重力为

$$ {F_{\mathrm{g}}}{\text{ = }}\frac{{{\rho _{\mathrm{p}}} - \rho }}{{{\rho _{\mathrm{p}}}}}{m_{\mathrm{p}}}g $$ (8) 式中: ${\rho _{\mathrm{p}}}$是粒子的密度;$\rho $是周围流体的密度;g是重力引起的加速度; $\dfrac{{{\rho _{\mathrm{p}}} - \rho }}{{{\rho _{\mathrm{p}}}}}$ 则代表浮力。当颗粒密度和周围流体密度相同时,其值接近于0,同时可忽略重力大小,在本仿真中颗粒材料为聚丙烯(C3H6),密度约为900 kg/m3,样品液材料为橄榄油,密度为900 kg/m3,两者密度一致,故不考虑重力因素。

由于仿真中设置的颗粒粒径较小,颗粒雷诺数${{Re} _{\mathrm{r}}} = \dfrac{{\rho {d_{\mathrm{p}}}|u - v|}}{\mu } < < 1$,故其曳力满足斯特克斯曳力模型:

$$ {{F = }}\frac{1}{{{\tau _{}}}}m(u - v) $$ (9) 式中:m为颗粒质量;$u$为流体速度;$v$为颗粒的速度;$\tau $为曳力系数,与流体密度和动力黏度以及颗粒的粒径有关,且有:

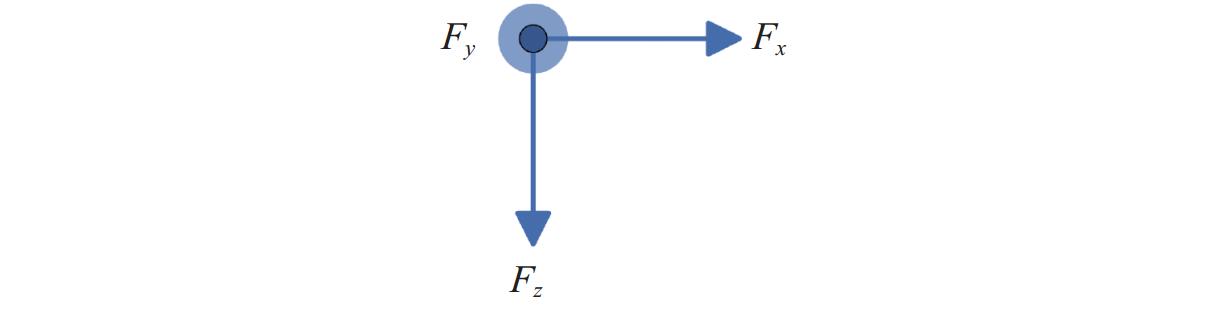

$$ \tau = \frac{{\rho {d^2}}}{{18\mu }} $$ (10) 在速度场中,流体速度分为${u_x}$、${u_y}$和${u_z}$,颗粒在流场中的受力分析如图6所示。

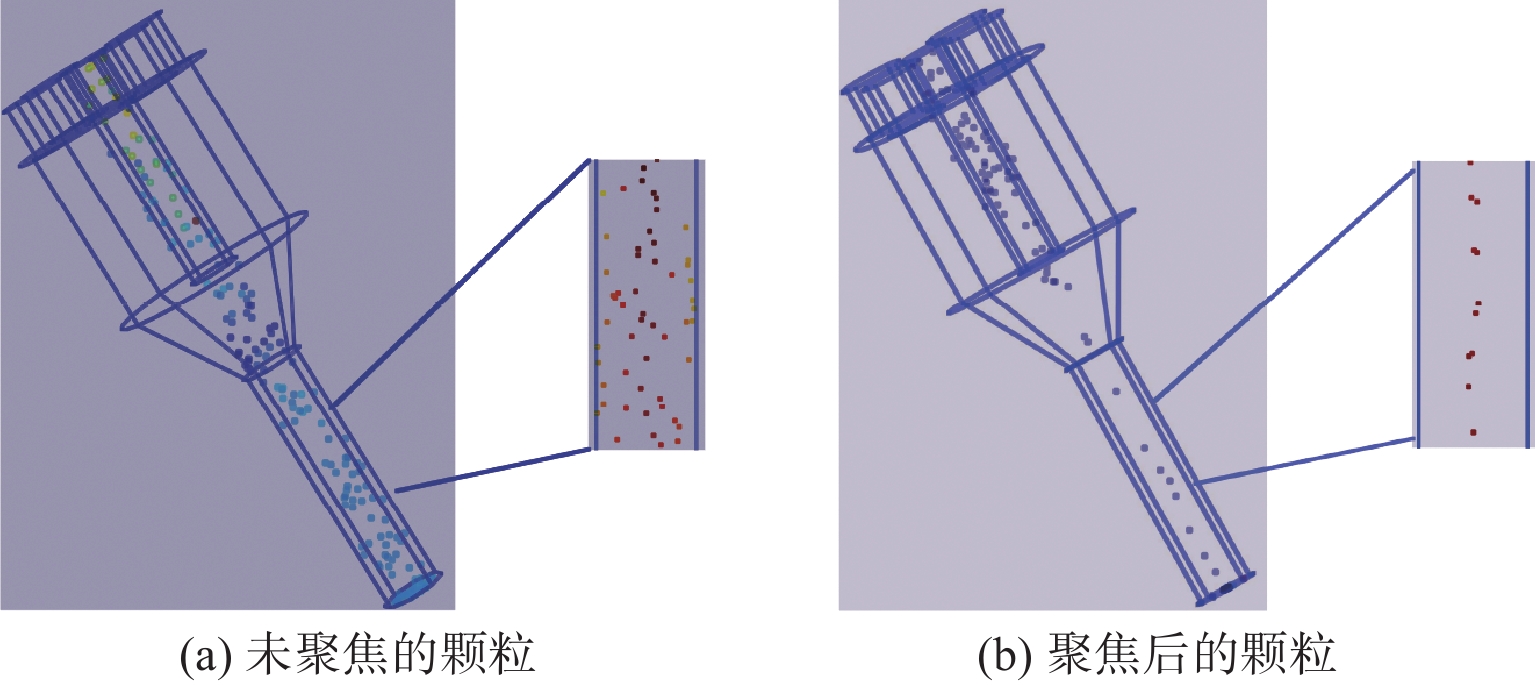

在样品流入口管中,颗粒主要受到曳力为${F_z}$;在鞘流系统的喷嘴处,鞘流对样品流有聚焦作用,样品流有了速度${u_x}$和速度${u_y}$,颗粒在流场中受力为${F_x}$和${F_y}$;在出口管中的聚焦流中,由于流体为层流状态,只存在z向速度${u_z}$,主要受到曳力为${F_z}$[14-15]。沿样品流入口边界随机释放一定数量的颗粒,对其在流场中的轨迹进行追踪,如图7所示。

图7(a)中颗粒在喷嘴中未受到聚焦的作用,流动轨迹沿y方向并未改变,样品流中颗粒充满出口管;图7(b)中颗粒流经喷嘴时,受x和y方向曳力影响,聚焦到圆管中心位置,进入出口管后在z方向曳力的影响下沿着直线流动。

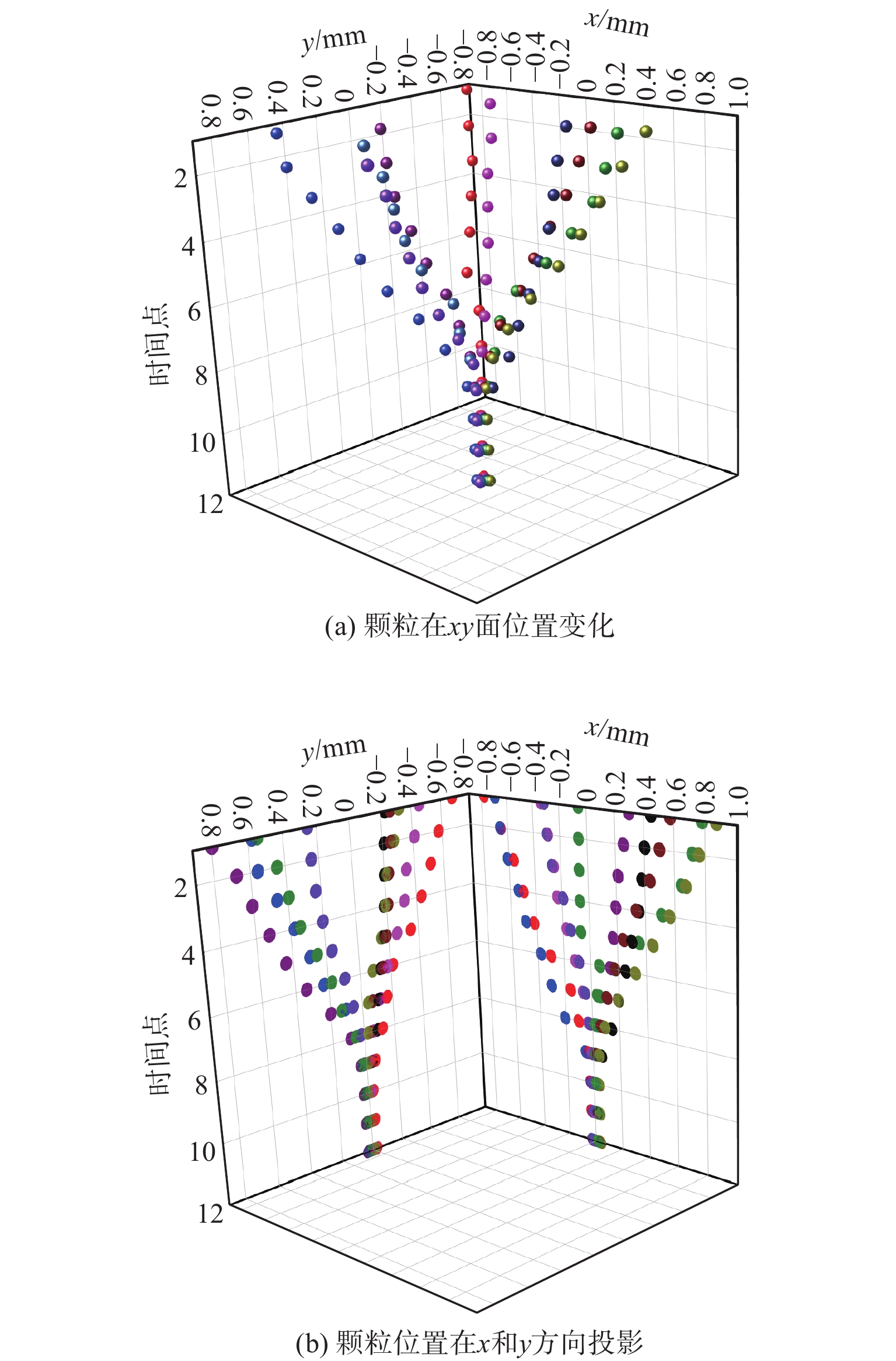

对颗粒从样品管道流出后经过喷嘴到达出口管道内的轨迹进行追踪,它们在x和y方向的位置变化如图8所示。

图中是不同时间释放颗粒,流道中心轴在xy面的投影为点(0,0)。图8(a)是颗粒在流动过程中在xy面上位置坐标随时间变化,颗粒进入聚焦区域后向中心轴靠拢,第8个时间后在出口流道中心处稳定下来。图8(b)是颗粒在y轴方向的位置随着时间的变化和在x轴方向的位置随着时间的变化,颗粒在x轴方向和y轴方向都在向中间靠拢。

3.2 重合误差影响因素研究

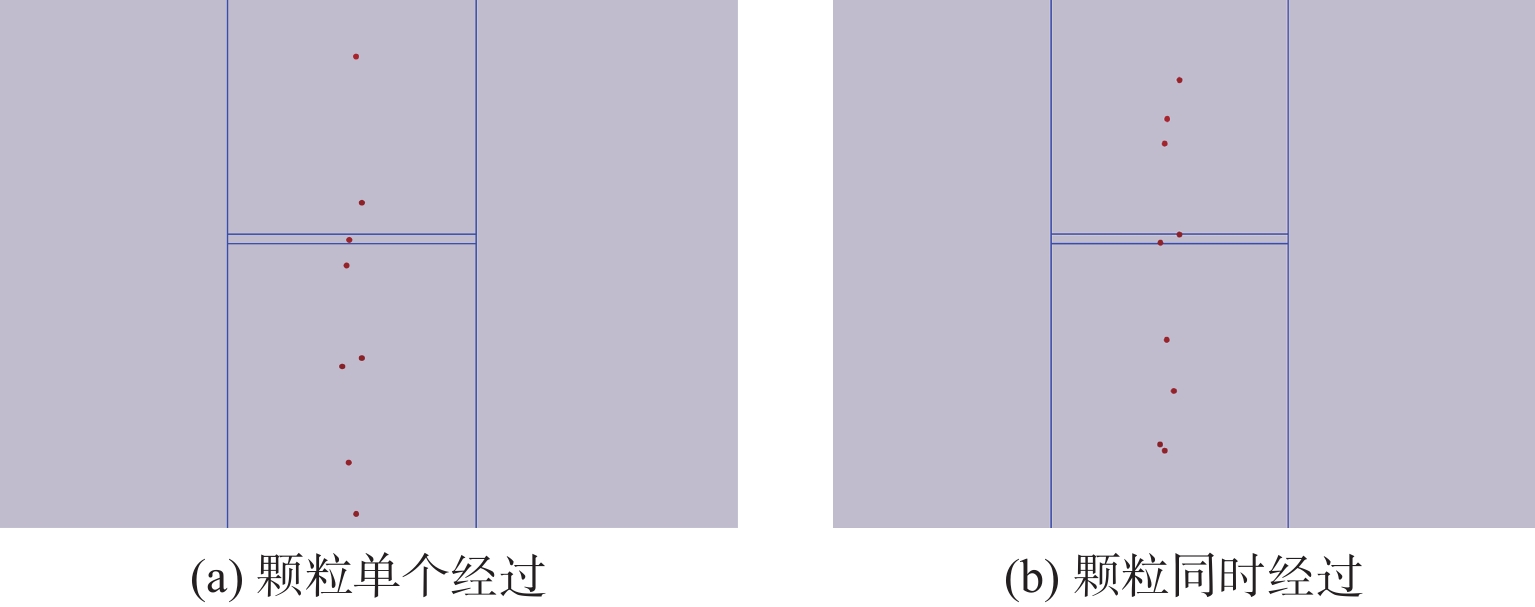

颗粒测量的本质是对单个颗粒经过光敏区(光线与样品流重叠的部分)时对产生的光脉冲的强度和数量进行检测[16],如图9所示,检测到的光脉冲的数量为颗粒数量测量结果,但当两个或两个以上颗粒同时存在光敏区时,产生的是一个叠加后的光脉冲,脉冲数量小于实际颗粒个数,由此产生的计数误差为重合误差。

在本仿真中,将样品流流过光敏区看作是不断充满光敏区的过程,设在一定时间内流经体积为v的光区的样品流体积为V,颗粒浓度为n,则V体积内的粒子数为T= n×V 。样品流充满光敏区的次数为V/v=N,当N很大时,则每次充满光敏区时同时存在的颗粒数量k的事件符合泊松分布,在光敏区内恰有k(k = 0,1,2,…,n)个粒子同时出现在光敏区的概率为

$$ p(k;nv) = {{\mathrm{e}}^{ - nv}}\frac{{{{(nv)}^k}}}{{k!}} $$ (11) 设恰有k个粒子同时出现在光敏区内的这类事件的发生次数为${N_k}$,则有:

$$ {N_0} + {N_1} + {N_2} + {N_3} + \cdots + {N_{{n}}}= N $$ (12) 并且:

$$ {N_k} = N\times p(k;nv) $$ (13) 式中${N_0}$是没有粒子(0个粒子)出现在光区内这种事件的次数,${N_0} = N{{\mathrm{e}}^{ - nv}}$。在光敏区内当粒子数大于等于1时都会产生一个脉冲,${T_0}$表示实测脉冲数,则有:

$$ {T_0} = {N_1} + {N_2} + {N_3} + \cdots + {N_{{n}}}= N - {N_0} = N(1 - {{\mathrm{e}}^{ - nv}}) $$ (14) V体积空气中的真实粒子数$T = nV = Nnv$,则光敏区因重叠而减少的粒子数为

$$ T - {T_0} = N(nv - 1 + {{\mathrm{e}}^{ - nv}}) $$ (15) 重合误差可计算为

$$ \frac{{T - {T_0}}}{T} = \frac{1}{{nv}}(nv - 1 + {{\mathrm{e}}^{ - nv}}) $$ (16) 式中看出重合误差只与颗粒浓度n和光敏区体积v有关。在本仿真中,聚焦流半宽度为d,光敏区厚度为r,则光敏区体积可计算为

$$ v = \pi {d^2}r $$ (17) 在产生聚焦流后,在样品流中释放颗粒,研究聚焦流宽度、颗粒浓度对重合误差的影响,如图10所示。

然后控制样品流宽度使光敏区体积v分别为0.001 5 mm3、0.002 5 mm3、0.003 5 mm3,再进行 5次颗粒浓度分布为5个/mm3、10个/mm3、15个/mm3、20个/mm3、25个/mm3的颗粒追踪仿真,统计方式为释放1 000个颗粒,对有颗粒经过光敏区的次数n进行统计,则重合误差可计算为$ \dfrac{{1\;000 - n}}{{1\;000}} $。

图11是不同光敏区体积下重合误差与颗粒浓度的关系曲线。无论在哪种光敏区体积下,在仿真中统计的重合误差与颗粒浓度的曲线都与理论曲线相差不大,且重合误差总是随着颗粒浓度增大而增大;从纵向来看,在每种颗粒浓度下,重合误差总是随着光敏区体积增大而增大,在高浓度时更为明显。

4 结论

本研究针对液体颗粒测量技术对检测精度的要求,引入鞘流技术,对用于液体颗粒测量的鞘流系统进行了仿真。通过COMSOL流场仿真计算得出的结果表明,可将样品流完美聚焦在0.24 mm的宽度,同时保证样品流宽度不偏离中心,并且在此宽度下可实现对颗粒的有效聚焦。以重合误差为研究对象,对重合误差的理论公式进行了推导,并研究了本设计中光敏区尺寸和颗粒浓度对重合误差的影响,与理论曲线大致相同。仿真结果证实了减小聚焦流宽度来压缩光敏区尺寸可有效降低重合误差发生的概率,并且随着样品流中颗粒浓度变大,聚焦流宽度对重合误差的影响更为明显。

-

[1] GERALD O. Detecting sub-50-nm particles in ultrapure water[J]. Chemical Engineering, 2012, 119(8): 14.

[2] 马鸿宇, 彭浩, 荣唯帅, 等. 基于单片机的滤膜阻塞式污染监测仪控制系统设计[J]. 南方农机, 2023, 54(17): 138-141. doi: 10.3969/j.issn.1672-3872.2023.17.038 MA Hongyu, PENG Hao, RONG Weishuai, et al. Design of control system for filter membrane blocking pollution monitor based on microcontroller[J]. China Southern Agricultural Machinery, 2023, 54(17): 138-141. doi: 10.3969/j.issn.1672-3872.2023.17.038

[3] 张奇芳, 范继来, 鞠薇薇, 等. 新型光学颗粒计数器研制及在医药分析中应用[J]. 中国测试, 2024, 50(5): 122-129. ZHANG Qifang, FAN Jilai, JU Weiwei, et al. Development of a new type optical particle counter and its application in pharmaceutical analysis[J]. China Measurement & Test, 2024, 50(5): 122-129.

[4] 刘东岳. 光散射法颗粒计数传感器的设计与研究[D]. 太原: 太原理工大学, 2018. LIU Dongyue. Design and research of light scattering particle count sensor[D]. Taiyuan: Taiyuan University of Technology, 2018.

[5] 陈明. 基于光阻法的液体颗粒计数系统研究[D]. 杭州: 浙江大学, 2021. CHEN Ming. Research on the liquid particle counting system based on photoresist method[D]. Hangzhou: Zhejiang University, 2021.

[6] ZHANG H. Development and performance detection of higher precision optical sensor for coal dust concentration measurement based on Mie scattering theory[J]. Optics and Lasers in Engineering, 2021, 144: 106642. doi: 10.1016/j.optlaseng.2021.106642

[7] PANWAR N, SONG P, TJIN C S, et al. Sheath-assisted hydrodynamic particle focusing in higher Reynolds number flows[J]. Journal of Micromechanics and Microengineering, 2018, 28(10): 105018. doi: 10.1088/1361-6439/aad493

[8] 刘婷婷. 流式细胞术在微生物检测中应用研究[D]. 上海: 上海师范大学, 2021. LIU Tingting. Application of flow cytometry in microorganism detection[D]. Shanghai: Shanghai Normal University, 2021.

[9] NORIKAZU S, DAISUKE K, MASAHIRO T. Concentration profiles of ions and particles under hydrodynamic focusing in Y-shaped square microchannel[J]. Scientific Reports, 2021, 11(1): 2585.

[10] SADEGHI A. Analytical solutions for mass transport in hydrodynamic focusing by considering different diffusivities for sample and sheath flows[J]. Journal of Fluid Mechanics, 2019, 862: 517-551. doi: 10.1017/jfm.2018.979

[11] HUANG D, WANG H, WANG X, et al. Investigation of optimal coupling velocities of the sample and sheath flows for hydrodynamic focusing[J]. Journal of Marine Science and Engineering, 2020, 8(8): 601. doi: 10.3390/jmse8080601

[12] PANWAR N, SONG P, YONG K, et al. Study of inertial hydrodynamic focusing in sheath-driven flows for lab-on-a-chip flow cytometry[C]//Proceedings of Optical Sensors 2017. Prague: SPIE, 2017: 10231.

[13] 鲁晨阳, 张佩, 王光辉, 等. 鞘流技术在气溶胶颗粒物光学传感器上的应用研究[J]. 中国激光, 2019, 46(1): 210-218. LU Chenyang, ZHANG Pei, WANG Guanghui. Application of sheath flow technique in aerosol particle sensor[J]. China Laser, 2019, 46(1): 210-218.

[14] 赵振希. 基于颗粒Stokes数的风力机叶片冲蚀磨损特性研究[D]. 兰州: 兰州理工大学, 2018. ZHAO Zhenxi. Study on the characteristics of wind turbine erosion in sand-wind environment based on the particle Stokes number[D]. Lanzhou: Lanzhou University of Technology, 2018.

[15] 刘中兴, 周一凡, 伍永福, 等. 3 kA钕电解槽流场中颗粒受力分析[J]. 中国稀土学报, 2020, 38(1): 90-99. doi: 10.1016/j.jre.2019.02.010 LIU Zhongxing, ZHOU Yifan, WU Yongfu. Force analysis of particle in flow field of 3 kA rare earth electrolysis cell[J]. China Rare Earth News, 2020, 38(1): 90-99. doi: 10.1016/j.jre.2019.02.010

[16] LUKAS O, NAKUL S, LARS H, et al. Minimizing the coincidence error in particle size spectrometers with digital signal processing techniques[J]. Journal of Aerosol Science, 2022, 165: 106039. doi: 10.1016/j.jaerosci.2022.106039

下载:

下载:

陕公网安备 61011302001501号

陕公网安备 61011302001501号