Effects of different preparation parameters on optical properties of porous TiO2 thin films

-

摘要:

多孔薄膜的制备工艺是其实现光学特性的重要环节。采用溶胶-凝胶法,以石英玻璃为基底,在不同工艺条件下制备出了多孔TiO2薄膜,并通过椭偏仪、分光光度计和白光干涉仪对薄膜光学性能进行了表征和分析,研究了原料配比、盐酸浓度、致孔剂聚乙二醇(polyethylene glycol,PEG)添加量等工艺参数对多孔TiO2薄膜折射率、孔隙率、透射率以及表面形貌的影响,并最终确定出制备多孔TiO2薄膜的优化工艺参数。结果表明,在300 nm~700 nm光谱范围内,采用钛酸丁酯、盐酸(20%)、去离子水和无水乙醇以3∶1∶10∶8的比例,且溶液中PEG添加量为0.03 g·ml−1,涂膜2次时,可将TiO2薄膜的折射率调低为1.496 0(波长550 nm);膜层孔穴分布较均匀,孔隙率为48.3%;薄膜光学带隙值为3.77 eV。

Abstract:The preparation process of porous thin films is an important part of their optical properties. The porous TiO2 films were prepared by sol-gel method and quartz glass substrate under different process conditions, the optical properties of the films were characterized and analyzed by ellipsometer, spectrophotometer and white light interferometer, and the effects of raw material ratio, hydrochloric acid concentration, the addition of porous agent (polyethylene glycol, PEG) and other process parameters on the refractive index, porosity, transmittance and surface morphology of porous TiO2 films were studied. Finally, the optimal process parameters for the preparation of porous TiO2 films were determined. The results show that in the spectral range of 300 nm~700 nm, the refractive index of TiO2 film can be reduced to 1.496 0 (wavelength 550 nm) when butyl titanate, hydrochloric acid (20%), deionized water and absolute ethanol are used in the ratio of 3∶1∶10∶8, the amount of PEG in the solution is 0.03 g·ml−1, and the film is coated twice. The pores of the film layer are evenly distributed, and the porosity is 48.3%. The optical bandgap value of the thin film is 3.77 eV.

-

Keywords:

- porous TiO2 thin film /

- sol-gel method /

- refractive index /

- porosity /

- transmittance /

- optical bandgap

-

引言

多孔薄膜因其纳米多孔网状骨架结构,具有孔隙率高、折射率低、介电常数小、密度小等特点,使其在光学、电学、热学、化学以及材料学等诸多领域具有广阔的应用前景。TiO2是一种重要的宽禁带半导体氧化物材料,因其价格低廉以及优异的物理和化学特性,使其在光催化[1-4]、光电转换[5-9]材料、气体/湿度敏感材料[10-11]等方面有着广泛的应用。当TiO2作为光学薄膜材料时,一般来说具有较高的折射率和介电常数,在传统分层介质减反膜和新型折射率渐变薄膜结构中,具有不可替代的优势[12]。由于TiO2的许多应用都与光吸收有关,因此,需要使用纳米多孔薄膜来增大其比表面积[13]。

国内外有很多种制备多孔TiO2薄膜的方法,总结起来主要分为液相法、气相沉积法和电化学法等。其中,液相法包括溶胶-凝胶法、溶剂挥发诱导自组装法、水热法和模板法等;气相沉积法一般包括磁控溅射法、电子束蒸发法和化学气相沉积法等;电化学法包括阳极氧化法、微弧氧化法和电沉积法等[14]。通常来说,各种方法制备的膜层性能存在较大差异,即使采用同一种方法,在不同的工艺参数下,制备的膜层性能也不尽相同。目前已有学者对多孔TiO2薄膜进行了相关研究。AZPIROZ R等[15]采用磁控溅射法,通过斜角沉积在钠钙玻璃上成功制备了多孔TiO2薄膜,探究了相对于靶材的角度、施加功率、总压力、氧气压力和沉积时间等沉积参数对薄膜形态的影响。ROY S等[16]采用浸渍提拉法在硅基底上制备了多孔TiO2薄膜,探究了添加不同浓度结构导向剂F127对薄膜形貌和电学特性的影响。LANDOLSI Z等[17]利用聚乙二醇(polyethylene glycol,PEG)通过溶胶-凝胶法成功制备了多孔TiO2薄膜,并对Fe2O3纳米颗粒修饰的多孔TiO2薄膜的电学和光催化性能进行了研究。VERNARDOU D等[18]利用水热合成法制备了多孔TiO2薄膜,原料采用钛酸四异丙酯、异丙醇和去离子水,探究了沉积时间对薄膜的影响。赵转清等[19]采用溶胶-凝胶法制备了多孔TiO2薄膜修饰的镍基电极,探究了烧结温度和聚乙二醇的含量对纳米薄膜表面形貌的影响。陆飞等[20]采用两步电压氧化法,在不同的条件下制备了多孔TiO2薄膜,探究了阳极氧化的最佳制备条件。王化平等[21]采用溶胶-凝胶法,以玻璃作为基底制备了多孔TiO2薄膜,探究了溶胶的粘度和稳定性对薄膜性能的影响。张兰等[22]利用溶胶-凝胶法制备了掺铁纳米多孔TiO2薄膜,研究了薄膜的表面形貌和晶体结构,获得了光催化性能最佳的掺杂量和退火温度。从查阅的文献资料来看,尚未见到对多孔TiO2薄膜光学特性进行系统研究,以及对制备工艺参数进行优化的报道。而制备工艺则是决定光学特性的关键,可以对膜层的折射率和消光系数进行精准地调控。

基于上述考虑,本文采用溶胶-凝胶法制备了多孔TiO2薄膜。溶胶-凝胶法是将易于水解的各种金属物质(无机化学盐或各种金属醇盐),在溶剂中发生水解,再经过缩合等过程,使之逐渐形成透明溶胶体系[23],其具有成本低、制备工艺简单、化学计量比易控等优点[24]。本文主要研究原料配比、盐酸浓度、致孔剂PEG添加量等工艺参数对多孔薄膜折射率、孔隙率、透射率以及光学带隙的影响,最后明确制备工艺与光学性能的关系,并确定出制备多孔TiO2薄膜的优化工艺参数。

1 实验

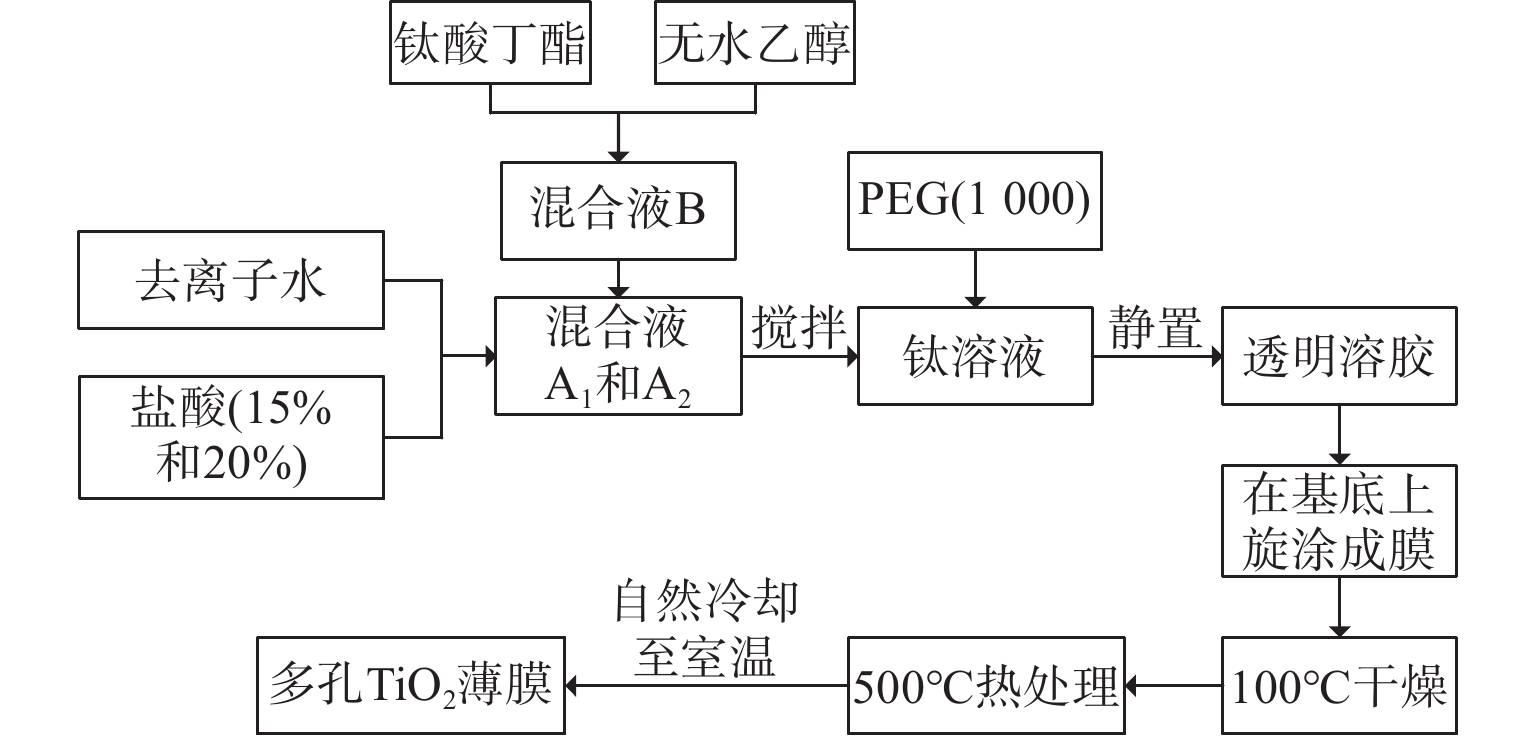

本实验选择钛酸丁酯、盐酸(体积质量分数为15%/L和20%/L)、去离子水和无水乙醇作为原材料,PEG(1 000)为致孔剂(PEG是一种高分子添加剂,经高温灼烧后可去除,并在薄膜中留下许多小孔洞[25])来制备薄膜。

具体实验流程如图1所示。详细介绍可参考文献[25],分别采用钛酸丁酯、盐酸(15%)、去离子水和无水乙醇以3∶2∶9∶8的比例,钛酸丁酯、盐酸(20%)、去离子水和无水乙醇以3∶1∶10∶8的比例配制溶液。首先,向2个干净的烧杯中倒入去离子水,一个加入盐酸(15%)形成混合液A1,一个加入盐酸(20%)形成混合液A2,然后将钛酸丁酯和无水乙醇在另一个烧杯中形成混合液B。用搅拌器高速搅拌混合液A1和A2,再将混合液B用滴管低速加入到混合液A1和A2中,在室温下搅拌1 h后,形成透明溶液。其次,在溶液中添加不同含量PEG,在室温下再搅拌1 h,获得透明溶胶,用保鲜膜封口,放在阴凉处静置一定时间后,将透明溶胶通过旋涂法涂膜。将经过预处理的石英玻璃基片固定在KW-4A匀胶机上,设定低速为500 r·min−1,旋转时间为7 s;高速为

3000 r·min−1,旋转时间为15 s。采用刻度滴管每次吸取0.5 ml溶胶滴在石英玻璃基片上,然后启动匀胶机,使其在石英玻璃基片上形成一层厚度均匀的薄膜。接下来,将其放在干燥箱中设置温度为100 ℃,干燥15 min后再继续旋涂下一层,确保每层薄膜都是均匀的。最后,将石英玻璃基片置入高温炉中,设置高温炉以2 ℃·min−1的速度升温至500 ℃,然后以500 ℃的温度保温2 h,自然冷却至室温后,即制得多孔TiO2薄膜。实验中共制备了8种多孔TiO2薄膜的石英玻璃样品,原料配比和PEG添加量如表1所示。样品S1~S4是钛酸丁酯、盐酸(15%)、去离子水和无水乙醇以3∶2∶9∶8的比例,并采用不同PEG(

1000 )添加量下制备的薄膜样品,涂膜2次;样品S5~S8是钛酸丁酯、盐酸(20%)、去离子水和无水乙醇以3∶1∶10∶8的比例,在不同PEG(1000 )添加量条件下制备的薄膜样品,涂膜2次。表 1 实验样品制备参数Table 1. Preparation parameters of experimental samples样品号 原料配比 PEG( 1000 )添加量/(g·ml−1)S1 3∶2(15%HCL)∶9∶8 0 S2 3∶2(15%HCL)∶9∶8 0.02 S3 3∶2(15%HCL)∶9∶8 0.03 S4 3∶2(15%HCL)∶9∶8 0.04 S5 3∶1(20%HCL)∶10∶8 0 S6 3∶1(20%HCL)∶10∶8 0.02 S7 3∶1(20%HCL)∶10∶8 0.03 S8 3∶1(20%HCL)∶10∶8 0.04 2 结果及分析

2.1 多孔TiO2薄膜的光学常数

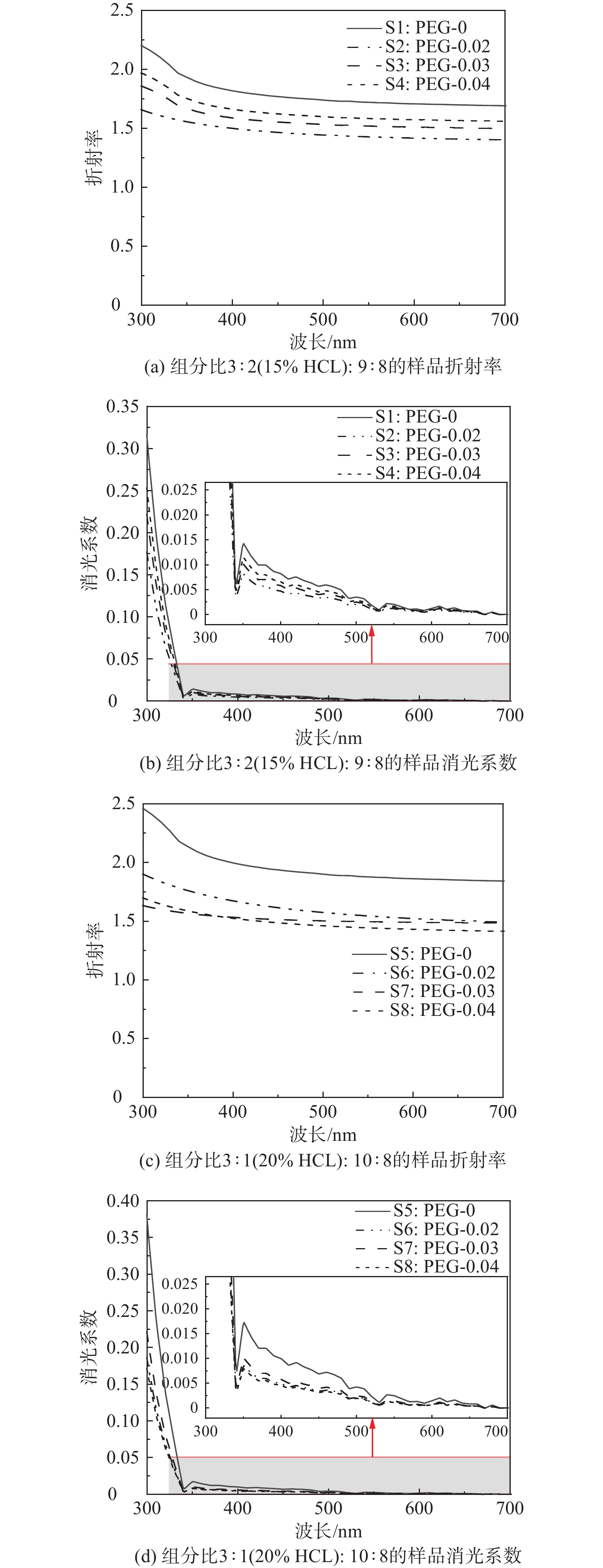

采用M-2000UI椭偏仪测量了不同条件下制备的多孔TiO2薄膜的折射率、消光系数和膜层厚度。从光学角度上看,可以将多孔TiO2看作是由TiO2和孔隙组成,因此可以通过在椭偏仪中建立有效介质近似(effective medium approximation,EMA)模型来拟合多孔薄膜的孔隙率。8种薄膜样品的折射率和消光系数色散曲线如图2所示。

从图2中可以看出,在300 nm ~700 nm光谱范围内,8种薄膜样品的折射率和消光系数均呈现出典型的色散特性,表明TiO2为正常色散材料,这与文献[26]的研究结果一致。

从图2(a)、2(c)可以看出,加入PEG的薄膜折射率普遍低于未加入PEG的薄膜,这是因为当加入致孔剂PEG形成多孔结构后,降低了薄膜的致密性。但是当采用不同比例、不同盐酸浓度时,其对折射率的影响程度和效果不同,具体表现在:对于图2(c)中采用钛酸丁酯、盐酸(20%)、去离子水和无水乙醇以3∶1∶10∶8的比例制备的薄膜,其折射率随着PEG添加量的增加而逐渐降低;而对于图2(a)中采用钛酸丁酯、盐酸(15%)、去离子水和无水乙醇以3∶2∶9∶8的比例制备的薄膜,其折射率随着PEG的加入而降低,但当PEG添加到一定程度时,折射率呈现上升的趋势。由此可知,在不同条件下,可通过调整PEG的含量进行多孔TiO2薄膜折射率的调控。

从图2(b)、2(d)中可以看出,在制备的8种薄膜样品中,无论是否加入PEG,薄膜都具有较小的消光系数,并且在可见光范围内趋于0。由于材料的消光系数可直接反映其吸收强度[26],由此可见,加入PEG后,几乎不会对多孔TiO2薄膜的吸收产生影响。

为了便于分析,将8种薄膜样品的折射率、厚度以及孔隙率分别列举出来,如表2所示。可以发现,添加PEG后的薄膜样品,其孔隙率增加,折射率明显降低。

表 2 薄膜样品的折射率、厚度以及孔隙率Table 2. Refractive index, thickness and porosity of thin film samples样本号 折射率(波长550 nm) 厚度/nm 孔隙率/% S1 1.7207 127.6 ― S2 1.4278 441.2 50.2 S3 1.5191 79.0 41.2 S4 1.5833 40.6 34.7 S5 1.8783 71.9 ― S6 1.5454 141.5 42.4 S7 1.4960 83.9 48.3 S8 1.4438 291.0 51.3 表2中,样本S5~S8为钛酸丁酯、盐酸(20%)、去离子水和无水乙醇以3∶1∶10∶8的比例制备的薄膜,随着PEG添加量的增加,其孔隙率逐渐增大,折射率逐渐降低,由此可见,多孔TiO2薄膜的折射率可以通过调节孔隙率来控制折射率,这与文献[13]所述一致;而样本S1~S4则为钛酸丁酯、盐酸(15%)、去离子水和无水乙醇以3∶2∶9∶8的比例制备的薄膜,其折射率和孔隙率不完全随PEG添加量的增加而发生变化。

2.2 多孔TiO2薄膜的光学带隙

采用U-

3501 分光光度计测量薄膜样品在300 nm ~700 nm光谱范围内的透射光谱,如图3所示。从图3可以看出,无论哪种组分比,在300 nm~700 nm光谱范围内,未加入致孔剂PEG的薄膜透射率较低,而加入PEG的薄膜透射率相对较高,对于多孔TiO2薄膜来说,未加入致孔剂PEG时膜层折射率较大,加入PEG后可有效降低膜层的折射率,这与图2的测量结果保持一致。但是随着PEG添加量的变化,透射率也表现出不同的变化,说明PEG可以对膜层的折射率进行有效调控。

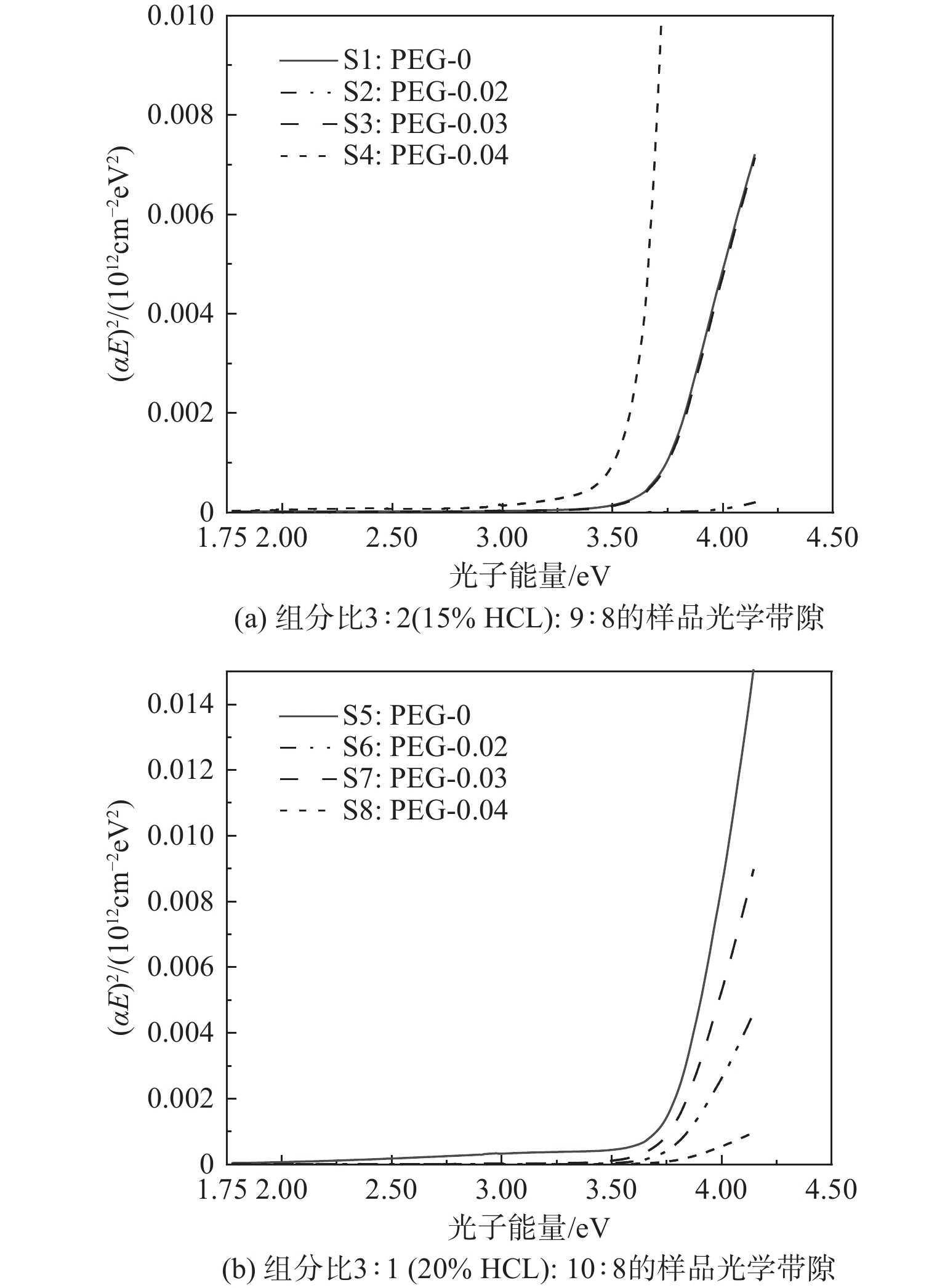

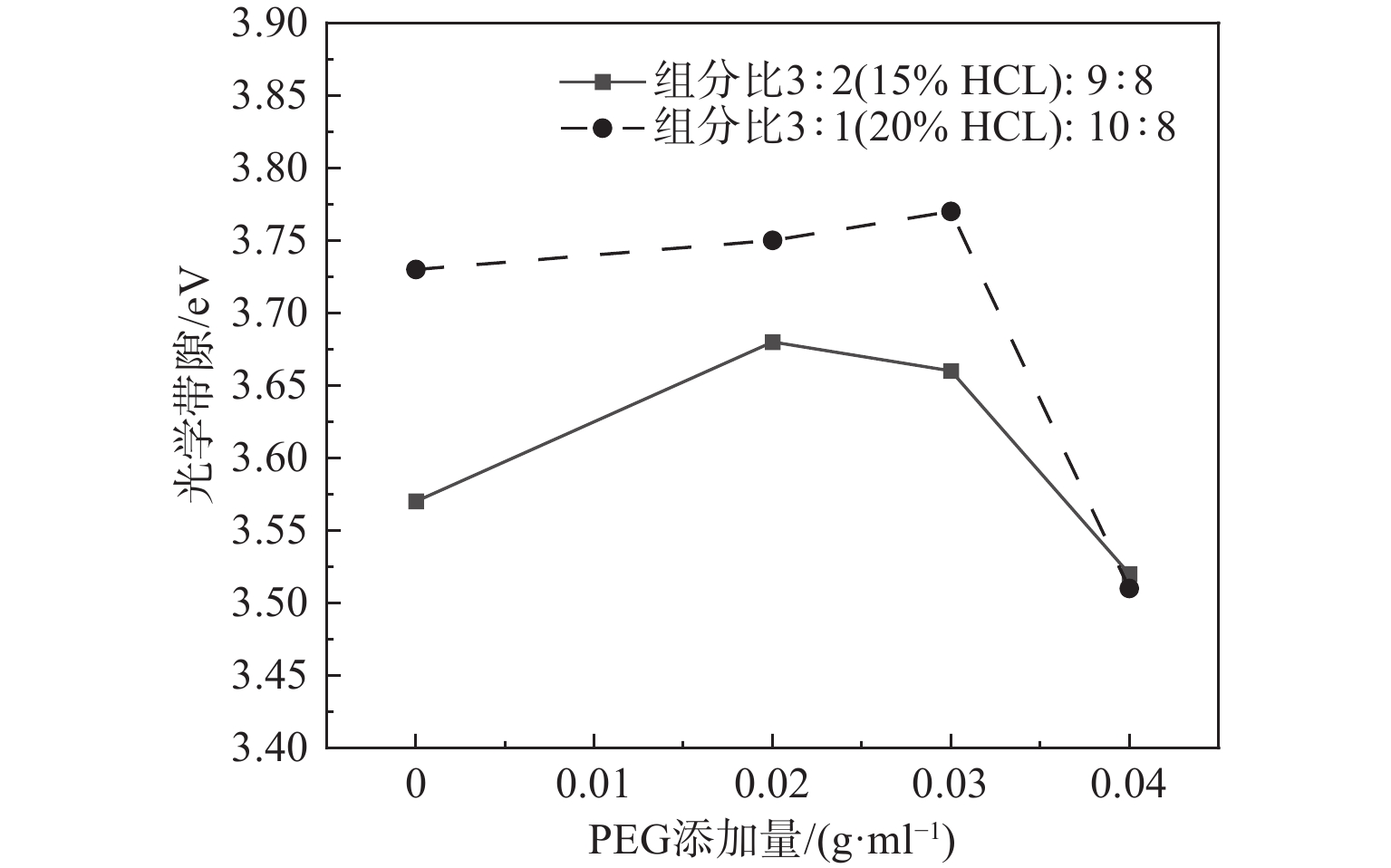

根据薄膜样品的透射光谱,基于Tauc关系,可做出$ \alpha {E}^{2}-h\nu $曲线,如图4所示。然后采用外延法通过反向延长$ \alpha {E}^{2} $曲线的线性部分,在光子能量$ h\nu $轴的截距就是薄膜的光学带隙,有关光学带隙的相关计算参考文献[27]。图5是不同PEG添加量的多孔TiO2薄膜的光学带隙。从图5中可以看出,采用钛酸丁酯、盐酸(15%)、去离子水和无水乙醇以3∶2∶9∶8的比例制备的薄膜,其光学带隙在3.52 eV ~3.68 eV之间;采用钛酸丁酯、盐酸(20%)、去离子水和无水乙醇以3∶1∶10∶8的比例制备的薄膜,其光学带隙在3.51 eV~3.77 eV之间。并且随着PEG添加量的增加,多孔TiO2薄膜的光学带隙先增加后减小,说明PEG对光学带隙具有一定的调控作用。

2.3 多孔薄膜表面形貌

经旋转涂膜后,制备的多孔TiO2薄膜表面平整,且呈透明状。图6为利用Zygo干涉仪观察到的多孔TiO2薄膜不同样品的表面形貌。

从图6可以看出,在TiO2溶胶中加入一定的PEG,有利于薄膜形成多孔结构。图6(b)、6(c)、6(d)的平均孔穴大小分别为30 μm、50 μm、70 μm,由此可以看出,随着PEG添加量的增加,孔隙尺寸逐渐增大,孔穴逐渐加深。并且当添加适量的PEG(

1000 )时,如图6(c),其孔穴分布比较均匀;而当PEG添加到一定程度时,如图6(d),会对孔的尺寸大小和孔穴的均匀分布产生一定的影响,这与文献[25]的结果一致。经对比可发现,当钛酸丁酯、盐酸(20%)、去离子水和无水乙醇以3∶1∶10∶8的比例制备薄膜时,溶液中PEG(1000 )添加量为0.03 g·ml−1,涂膜2次时,薄膜孔穴分布较均匀,孔密度大,此时其孔隙率为48.3%。3 结论

本文采用溶胶-凝胶法以旋转涂膜工艺制备了多孔TiO2薄膜。利用椭偏仪、分光光度计和白光干涉仪对多孔TiO2薄膜进行表征后,发现当多孔薄膜添加致孔剂PEG后,改变了薄膜的纳米孔径尺寸,从而影响了薄膜的折射率和透射性。研究表明,在不同条件下,可通过调控PEG的含量获得不同折射率的多孔TiO2薄膜。

经对比分析,确定了采用溶胶-凝胶法制备多孔TiO2薄膜的优化工艺参数,即钛酸丁酯、盐酸(20%)、去离子水和无水乙醇以3∶1∶10∶8的比例制备薄膜,使溶液中PEG(

1000 )的浓度为0.03 g·ml−1,涂膜2次。采用此工艺参数在石英基底上制备的多孔TiO2薄膜,在300 nm~700 nm光谱范围内折射率可以降低至1.496 0,薄膜光学带隙值为3.77 eV,孔穴大小分布较均匀,孔隙率为48.3%。 -

表 1 实验样品制备参数

Table 1 Preparation parameters of experimental samples

样品号 原料配比 PEG( 1000 )添加量/(g·ml−1)S1 3∶2(15%HCL)∶9∶8 0 S2 3∶2(15%HCL)∶9∶8 0.02 S3 3∶2(15%HCL)∶9∶8 0.03 S4 3∶2(15%HCL)∶9∶8 0.04 S5 3∶1(20%HCL)∶10∶8 0 S6 3∶1(20%HCL)∶10∶8 0.02 S7 3∶1(20%HCL)∶10∶8 0.03 S8 3∶1(20%HCL)∶10∶8 0.04 表 2 薄膜样品的折射率、厚度以及孔隙率

Table 2 Refractive index, thickness and porosity of thin film samples

样本号 折射率(波长550 nm) 厚度/nm 孔隙率/% S1 1.7207 127.6 ― S2 1.4278 441.2 50.2 S3 1.5191 79.0 41.2 S4 1.5833 40.6 34.7 S5 1.8783 71.9 ― S6 1.5454 141.5 42.4 S7 1.4960 83.9 48.3 S8 1.4438 291.0 51.3 -

[1] 郭俊雄, 李奕奕, 李尚栋, 等. 一步法制备TiO2/石墨烯复合多孔薄膜应用于增强光催化活性及光伏性能[J]. 中国催化学报, 2020, 41(8): 1208-1216. doi: 10.1016/S1872-2067(19)63511-4 GUO Junxiong, LI Yiyi, LI Shangdong, et al. One-step fabrication of TiO2/graphene hybrid mesoporous film with enhanced photocatalytic activity and photovoltaic performance[J]. Chinese Journal of Catalysis, 2020, 41(8): 1208-1216. doi: 10.1016/S1872-2067(19)63511-4

[2] SADIKIN S N, RIDWAN J, ALI UMAR M I, et al. Photocatalytic activity and stability properties of porous TiO2 film as photocatalyst for methylene blue and methylene orange degradation[J]. International Journal of Electrochemical Science, 2023, 18(9): 100246. doi: 10.1016/j.ijoes.2023.100246

[3] LANDOLSI Z, BEN ASSAKER I, NUNES D, et al. Synthesis and characterization of porous TiO2 film decorated with bilayer hematite thin film for effective photocatalytic activity[J]. Inorganic Chemistry Communications, 2022, 144: 109865. doi: 10.1016/j.inoche.2022.109865

[4] ANGULO-IBÁÑEZ A, GOITANDIA A M, ALBO J, et al. Porous TiO2 thin film-based photocatalytic windows for an enhanced operation of optofluidic microreactors in CO2 conversion[J]. iScience, 2021, 24(6): 102654. doi: 10.1016/j.isci.2021.102654

[5] 张翱, 张春梅, 吴魏霞, 等. 丝网印刷制备染料敏化太阳能电池[J]. 光谱学与光谱分析, 2021, 41(7): 2321-2324. ZHANG Ao, ZHANG Chunmei, WU Weixia, et al. Study on dye-sensitized solar cell by screen printing[J]. Spectroscopy and Spectral Analysis, 2021, 41(7): 2321-2324.

[6] LI Q, QI J Q, SONG J, et al. The optical and electrical properties regulation of TiO2 mesoporous thin film in perovskite solar cells[J]. Journal of Materials Science: Materials in Electronics, 2021, 32(1): 277-289. doi: 10.1007/s10854-020-04770-0

[7] SHAKIR S, ABD-UR-REHMAN H M, ZAHID R, et al. Multistep electrophoretic deposition of TiO2 film and its surface modification for dye sensitized solar cells[J]. Journal of Alloys and Compounds, 2020, 837: 155579. doi: 10.1016/j.jallcom.2020.155579

[8] BAYAT A, SAIEVAR-IRANIZAD E, BAYATLOO E, et al. Highly porous film of TiO2 nanoparticles synthesized using carbon nanospheres for highly efficient dye-sensitized solar cells[J]. The European Physical Journal Plus, 2020, 135(2): 195. doi: 10.1140/epjp/s13360-020-00241-x

[9] AN S Y, GAO Q Q, ZHANG X Y, et al. Introducing of MnS passivation layer on TiO2 mesoporous film for improving performance of quantum dot sensitized solar cells[J]. Journal of Alloys and Compounds, 2019, 799: 351-359. doi: 10.1016/j.jallcom.2019.05.277

[10] 张韩霞. 基于半导体纳米薄膜的酒精气敏传感器构建及性能研究[D]. 天津: 天津理工大学, 2016. ZHANG Hanxia. Construction and performance study of alcohol gas sensor based on semiconductor nano-film[D]. Tianjin: Tianjin University of Technology, 2016.

[11] 王宇. 基于硅纳米孔柱阵列的多孔TiO2复合薄膜湿敏特性研究[D]. 哈尔滨: 黑龙江大学, 2019. WANG Yu. Study on humidity-sensitive characteristics of porous TiO2 composite film based on silicon nanoporous column array[D]. Harbin: Helongjiang University, 2019.

[12] 荆建行. 离子束辅助低损耗TiO2光学薄膜研究[D]. 成都: 中国科学院大学(中国科学院光电技术研究所), 2021. JING Jianxing. Study on low-loss TiO2 optical thin films assisted by ion beam[D]. Chengdu: Institute of Optics and Electronics, Chinese Academy of Sciences, 2021.

[13] LEE J, LEE M. Effect of TiCl4 treatment on the refractive index of nanoporous TiO2 films[J]. Applied Surface Science, 2015, 357: 659-665. doi: 10.1016/j.apsusc.2015.09.075

[14] 肖峰, 陈成, 刘莉, 等. 电化学法制备TiO2多孔薄膜专利分析[J]. 中国科技信息, 2018(11): 38-41. doi: 10.3969/j.issn.1001-8972.2018.11.011 XIAO Feng, CHEN Cheng, LIU Li, et al. Patent analysis of TiO2 porous film prepared by electrochemical method[J]. China Science and Technology Information, 2018(11): 38-41. doi: 10.3969/j.issn.1001-8972.2018.11.011

[15] AZPIROZ R, CARRETERO E, CUEVA A, et al. In-flow photocatalytic oxidation of NO on glasses coated with nanocolumnar porous TiO2 thin films prepared by reactive sputtering[J]. Applied Surface Science, 2022, 606: 154968. doi: 10.1016/j.apsusc.2022.154968

[16] ROY S, GHOSH S P, PRADHAN D, et al. Morphological and electrical study of porous TiO2 films with various concentrations of Pluronic F-127 additive[J]. Journal of Porous Materials, 2021, 28(1): 231-238. doi: 10.1007/s10934-020-00983-0

[17] LANDOLSI Z, BEN ASSAKER I, NUNES D, et al. Enhanced electrical and photocatalytic properties of porous TiO2 thin films decorated with Fe2O3 nanoparticles[J]. Journal of Materials Science: Materials in Electronics, 2020, 31(23): 20753-20773. doi: 10.1007/s10854-020-04588-w

[18] VERNARDOU D, KALOGERAKIS G, STRATAKIS E, et al. Photoinduced hydrophilic and photocatalytic response of hydrothermally grown TiO2 nanostructured thin films[J]. Solid State Sciences, 2009, 11(8): 1499-1502. doi: 10.1016/j.solidstatesciences.2009.05.014

[19] 赵转清, 姚素薇, 张卫国, 等. 多孔TiO2纳米薄膜的制备及PEG对其表面形貌的影响[J]. 材料导报, 2002, 16(5): 75-76. ZHAO Zhuanqing, YAO Suwei, ZHANG Weiguo, et al. Preparation of porous nanosized TiO2 film and the effect of PEG on the morphology of it[J]. Materials Review, 2002, 16(5): 75-76.

[20] 陆飞, 丁孝飞, 王赫, 等. 阳极氧化法制备TiO2多孔薄膜及其光电化学性能研究[J]. 电镀与精饰, 2015, 37(10): 1-5. LU Fei, DING Xiaofei, WANG He, et al. Anodic oxidation and photoelectrochemical properties of the nanoporous titania films[J]. Plating & Finishing, 2015, 37(10): 1-5.

[21] 王化平, 梁小平, 任素娥, 等. 溶胶-凝胶法制备多孔TiO2薄膜的研究[J]. 徐州工程学院学报(自然科学版), 2012, 27(4): 74-79. WANG Huaping, LIANG Xiaoping, REN Sue, et al. Study on the preparation of porous TiO2 film by Sol-gel method[J]. Journal of Xuzhou Institute of Technology (Natural Sciences Edition), 2012, 27(4): 74-79.

[22] 张兰, 马鑫, 马会中. 掺铁纳米TiO2多孔薄膜的制备及光催化性能研究[J]. 工业安全与环保, 2019, 45(10): 83-85. ZHANG Lan, MA Xin, MA Huizhong. Preparation and photocatalytic properties of iron doped TiO2 porous films[J]. Industrial Safety and Environmental Protection, 2019, 45(10): 83-85.

[23] ALAM M J, CAMERON D C. Optical and electrical properties of transparent conductive ITO thin films deposited by sol–gel process[J]. Thin Solid Films, 2000, 377: 455-459.

[24] FUERTES M C, BARRERA M P, PLÁ J. Sorption and optical properties of sol–gel thin films measured by X-ray reflectometry and ellipsometric porosimetry[J]. Thin Solid Films, 2012, 520(15): 4853-4862. doi: 10.1016/j.tsf.2012.03.018

[25] 陈霞. TiO2薄膜及其多孔薄膜的溶胶—凝胶法制备与表征[D]. 呼和浩特: 内蒙古师范大学, 2009. CHEN Xia. Preparation and characterization of TiO2 film and its porous film by sol-gel method[D]. Hohhot: Inner Mongolia Normal University, 2009.

[26] 徐均琪, 李候俊, 李绵, 等. 热蒸发沉积TiO2薄膜的光学及激光损伤特性[J]. 真空, 2019, 56(1): 39-44. XU Junqi, LI Houjun, LI Mian, et al. Optical and laser damage characteristics of TiO2 films prepared by thermal evaporation deposition technique[J]. Vacuum, 2019, 56(1): 39-44.

[27] XU J Q, SU J H, HANG L X, et al. Influence of electric field on laser damage properties of DLC films by unbalanced magnetron sputtering[J]. Applied Surface Science, 2013, 265: 234-238. doi: 10.1016/j.apsusc.2012.10.185

下载:

下载:

陕公网安备 61011302001501号

陕公网安备 61011302001501号