Visual inspection method of detecting flaws on optical glasses surface

-

摘要: 介绍了一种基于计算机视觉检测光学镜片外观瑕疵的方法。该方法主要针对麻点、划痕、毛刺和破边等瑕疵,并根据瑕疵在侧面光源作用下发生漫反射,产生亮光斑或亮光带的原理,开发了基于反射检测法的瑕疵检测装置,检测装置的工作节拍不超过5 s/片。创新使用了黑体作为暗背景,提高了瑕疵的对比度。视觉检测中利用了总面积检测法来检测镜片表面的麻点和划痕,利用边缘毛刺检测法来检测镜片边缘的毛刺和破边。在试验中检测了53块直径10 mm的镜片,准确率达到100%。最后给出了基于31万像素CCD的检测结果,其中OK镜片总瑕疵量≤100 pixel,最高灰度值≤80,麻点和划痕镜片的总瑕疵量介于200 pixel~600 pixel之间,最高灰度值≤210,毛刺/破边镜片总瑕疵量≤100 pixel,最高灰度值介于200~255之间,可见麻点镜片和划痕镜片的总瑕疵量明显比毛刺/破边镜片和OK镜片高。Abstract: A computer visual inspection method for detecting flaws on optical glasses surface was introduced. This method mainly aimed at detecting flaws such as pockmark, scratch, burr, edge damage and so on. According to the principle that bright spots and bright bands generated by the diffuse reflection of flaws under the action of side light, the flaws detection device based on reflection detection method was developed, and the work cycle of the device was less than 5 s per piece. The blackbody was creatively used to form the dark background and enhance the contrast. In the visual inspection, the total area detection method was used to detect the pockmark and scratch of glasses surface, and the edge burr detection method was used to detect the burr and edge damage of glasses edge. In the experiment, 53 pieces of 10mm diameter optical glasses were tested and the accuracy reached 100%. In the end, the detection result based on the 310 000 pixel CCD was given. According to the result, the total number of flaws on OK glasses is ≤100 (pixel), and the maximum gray value is ≤80. The total number of flaws on pockmark and scratch glasses is between 200 and 600 (pixel), and the maximum gray value is ≤210. The total number of flaws on burr/edge damage glasses is ≤100 (pixel), and the maximum gray value is between 200~255. Thus it can be seen that, the total number of flaws on pockmark and scratch glasses is obviously higher than that of flaws on burr/edge damage and OK glasses.

-

Keywords:

- optical glasses /

- flaws /

- surface inspection /

- visual inspection

-

引言

光学玻璃镜片是光学玻璃经过切割、研磨、清洗、镀膜等操作后得到的镜片[1-2]。在加工和处理的过程中稍有不慎便容易在镜片上形成瑕疵,如划痕、麻点、毛刺、破边等[3]。这些瑕疵既影响镜片美观又影响镜片的基本功能[4-5],而且这些瑕疵使光发生散射,会造成能量损失并且会使镜片发热[6-7]。传统的光学玻璃镜片瑕疵检测采用人工检测的方法。人工检测不仅效率低而且容易造成误判,今后光学镜片外观瑕疵检测将朝着自动化检测的方向发展[8]。

目前已有镜片瑕疵视觉在线检测方法[9],其采用了两级采集系统进行数据的采集,虽然提高了采集精度,但使用了2套视觉系统,增加了检测的经济成本;还有基于显微散射暗场成像的球面光学元件表面缺陷评价系统[10-12],该方法在镜片表面拍摄多张子孔径图像,经过矫正和拼接后再进行特征提取,其检测速度为6 s/片,检测速度较慢;以及透镜的磁悬浮检测[13-14],该方法检测的精度不高,只能检测外形缺陷以及气泡等缺陷,无法检测透镜表面细微的瑕疵。本文提出了一种新的通过计算机视觉采集玻璃镜片表面图像,然后进行图像分析来检测光学玻璃镜片表面瑕疵的方法。该方法简便实用,成本低,准确率高,且检测速度可达5 s/片。

1 检测原理

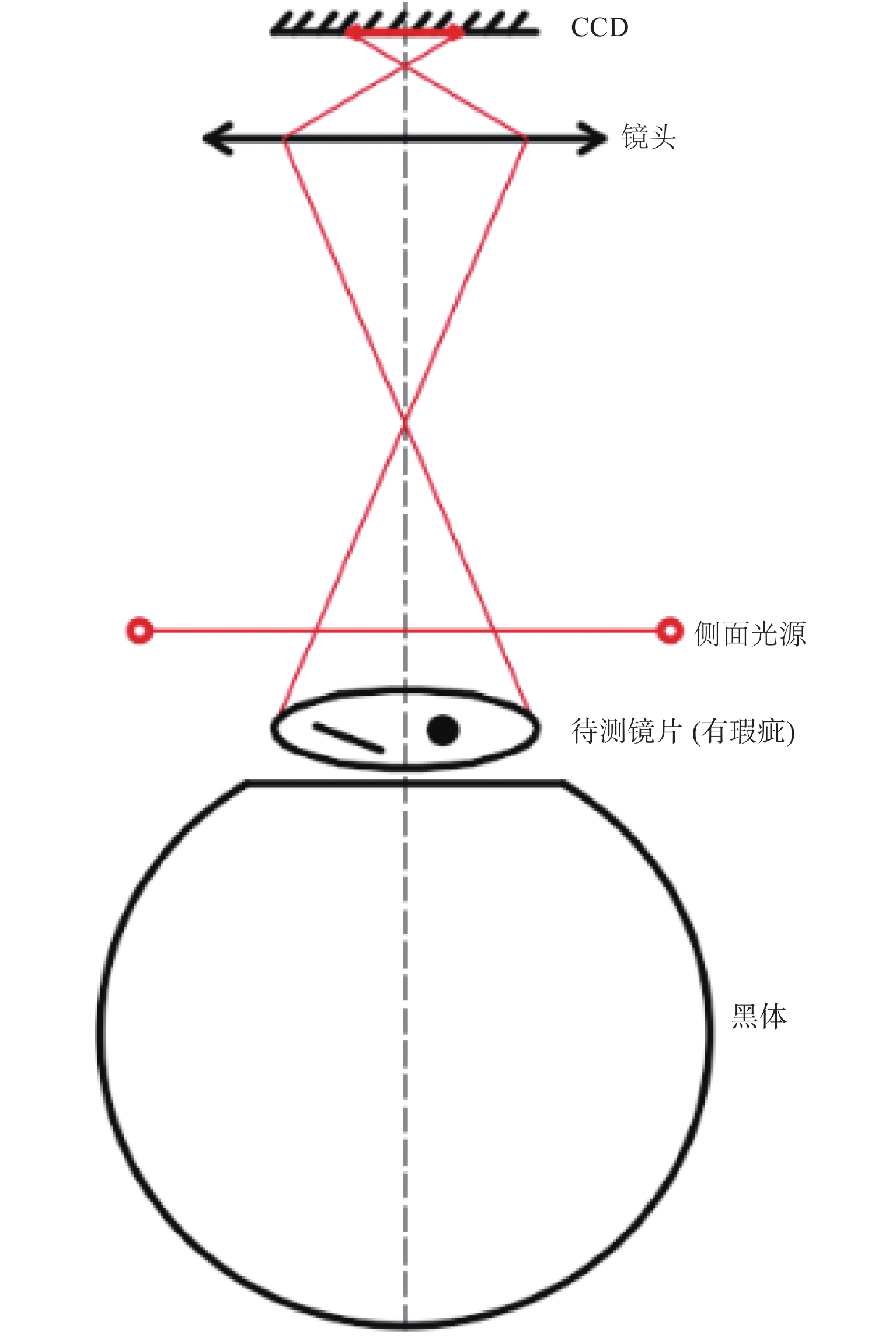

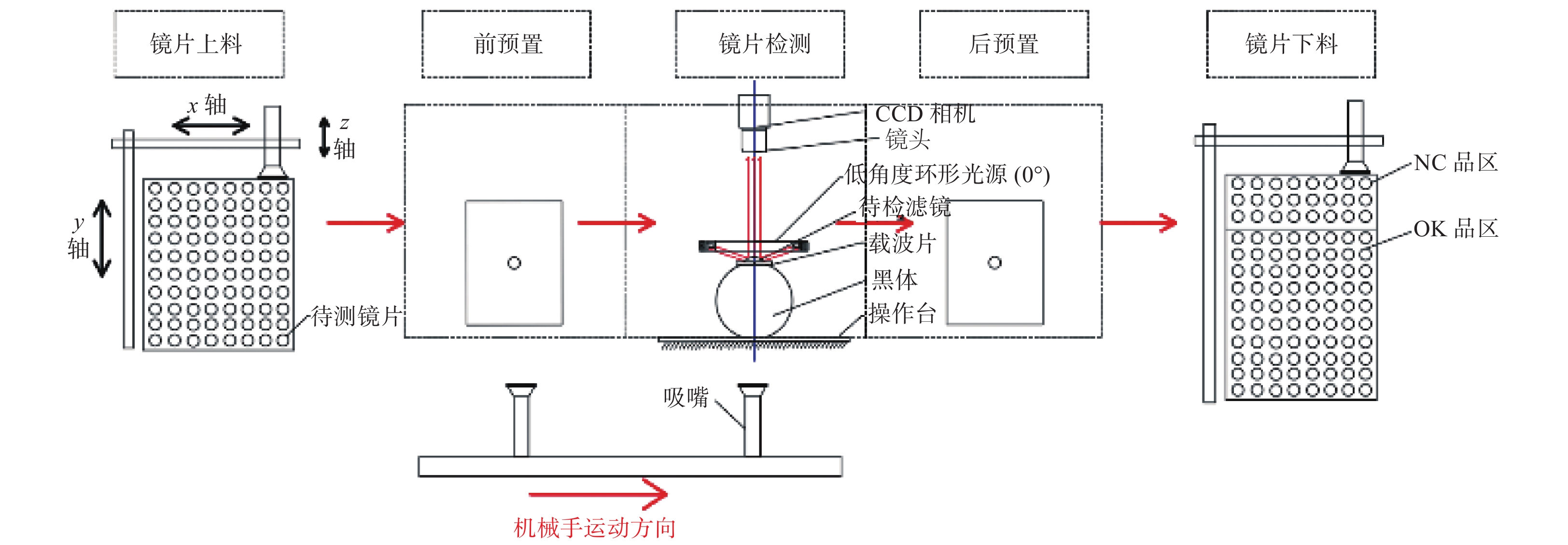

根据 GB/T 1185-2006(光学零件表面疵病)[15],光学零件的表面疵病分类有麻点、斑点、擦痕、破边等,该方法可用于检测麻点、划痕、毛刺和破边等瑕疵。检测方案如图1所示。

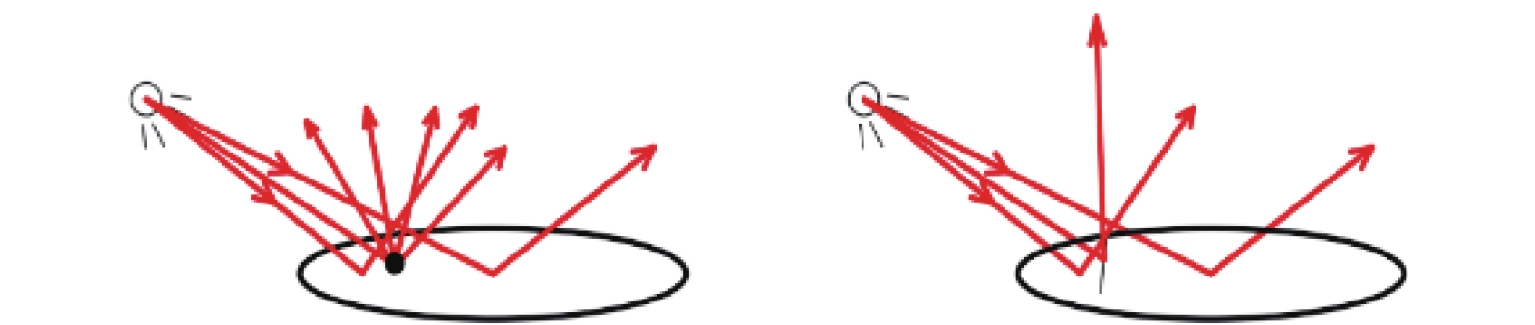

利用光在麻点表面发生漫反射,在划痕表面发生漫反射或镜面反射,在毛刺和破边表面发生漫反射的特点,如图2所示。在侧面光源的作用下,瑕疵会在CCD表面形成亮斑或亮光带。由于光在划痕表面可能会发生镜面反射,只有朝垂直于划痕延伸的方向打光才能在图像上凸显出划痕,所以应选用低角度的环形光源打光。

瑕疵检测方法为反射法检测,采用的是低角度环形光源(角度为0°)。在上述的检测方案中使用到了黑体,放置于玻璃镜片下方。黑体的作用是吸收玻璃镜片周围的环境光,形成暗背景,入射光线进入黑体,经过多次反射后被吸收,以热的形式向外辐射。

2 外观瑕疵检测方法

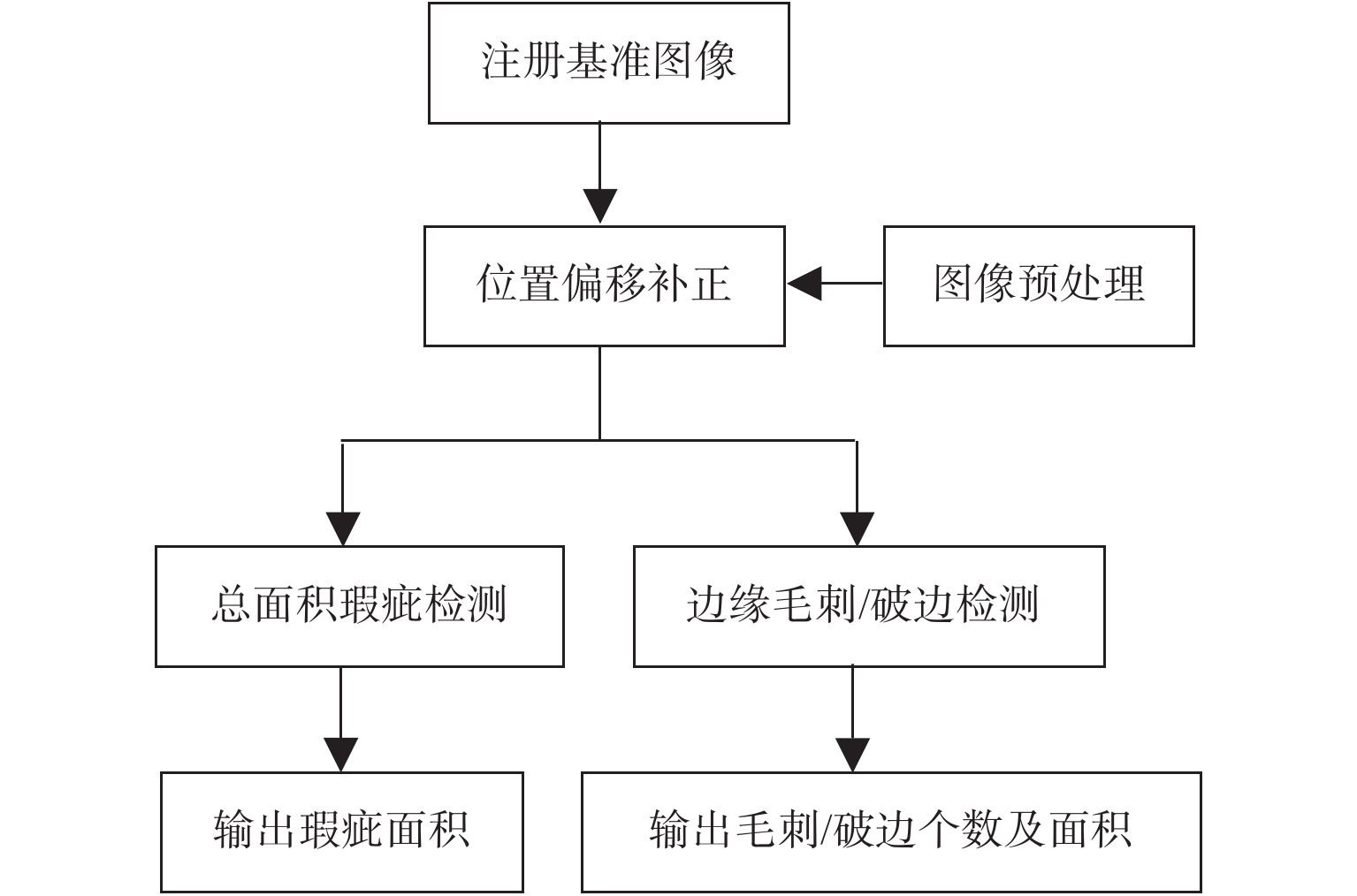

镜片检测过程分为4步,分别为注册基准图像、位置偏移补正、总面积瑕疵检测以及边缘瑕疵检测,如图3所示。

2.1 位置偏移补正

进行位置偏移补正是检测移动物体必要的操作,在实验中依托的CV-X视觉系统的位置偏移补正分3步进行,分别是:图形搜索、X/Y位置补正和角度补正。

2.2 图像预处理

进行图像预处理是为了改善图像品质和性能,为下一步瑕疵检测做准备。

2.3 总面积瑕疵检测法

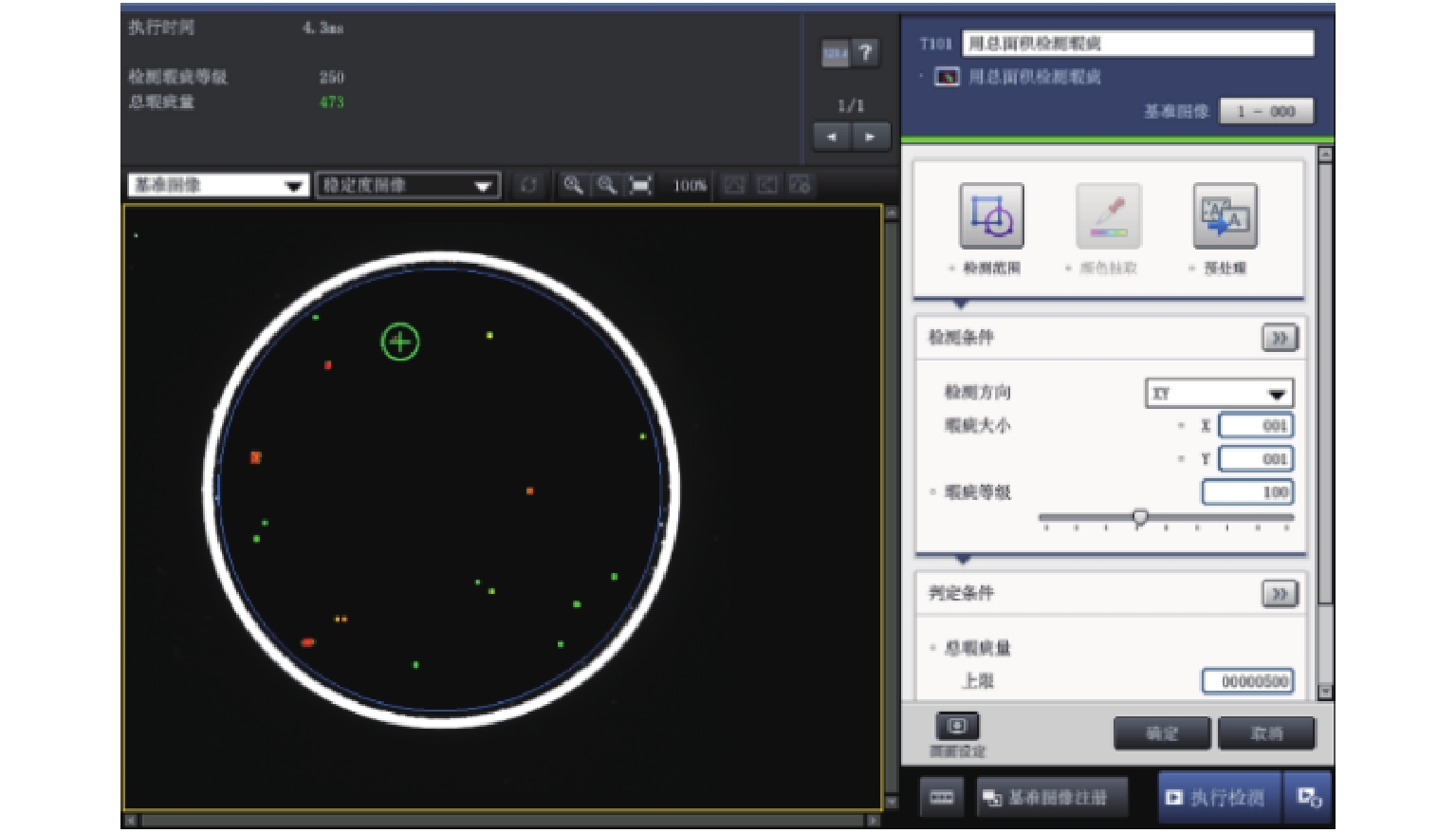

总面积瑕疵检测法是将检测范围内与背景相比存在一定灰度差的像素点识别为瑕疵。其过程分为3步,分别为设定检测范围、设定检测条件、设定判定条件,如图4所示。

首先设定检测范围,由于镜片俯视图呈圆形,有明显的边缘分界,在设定检测范围时应设定为圆。其次设定检测条件,检测条件有检测方向,瑕疵大小和瑕疵等级3项。检测方向由于X和Y方向都需要进行检测,所以选择XY方向;设定瑕疵的大小指的是设定所检测的最高精度瑕疵的像素值;设定瑕疵的等级指的是设定所检测瑕疵的最低灰度值,只有灰度值大于该瑕疵等级的瑕疵才能被检测出来。最后设定判定条件,由OK镜片的参数决定,主要的判定条件为瑕疵总量的上限值。

2.4 边缘瑕疵检测法

边缘瑕疵检测法针对毛刺和破边两类瑕疵,其原理是将拟合圆轮廓信息与待测圆轮廓信息相比较,出入较大的位置设定为瑕疵,并且输出瑕疵总量和瑕疵数。其检测过程分为4步,分别是设定检测范围、设定边缘检测条件、设定缺陷检测条件和设定判定条件。如图5所示。

第一,设定检测范围,进行边缘毛刺和破边检测时,检测的范围是镜片的边缘轮廓,所以检测范围应设定为圆环。第二,设定边缘检测条件,需要设定检测方向和边缘方向。其作用是选择检测镜片轮廓的内边界或外边界。第三,设定缺陷检测条件,需要设定基准模型线、缺陷检测方向和检测阈值。基准模型线是指通过待测镜片的外形轮廓数据生成的拟合信息,该试验中设定为圆;缺陷检测方向设定为双方向,因为需要同时检测凸起和下凹缺陷。检测阈值通过试验得来。第四,设定判定条件,由OK镜片的参数决定,主要的判定条件为瑕疵数和瑕疵总量

3 试验装置设计与试验结果分析

设计了试验检测装置,总体机械方案如图6所示,共有镜片上料,前预置,镜片检测,后预置和镜片下料5个工位。使用三菱PLC实现自动化检测[16-17],工作节拍不超过5 s/片。

使用上面提到的检测方法,我们检测了53块直径10 mm的镜片,准确率达到100%。检测结果如表1所示。

部分试验数据如表2所示。

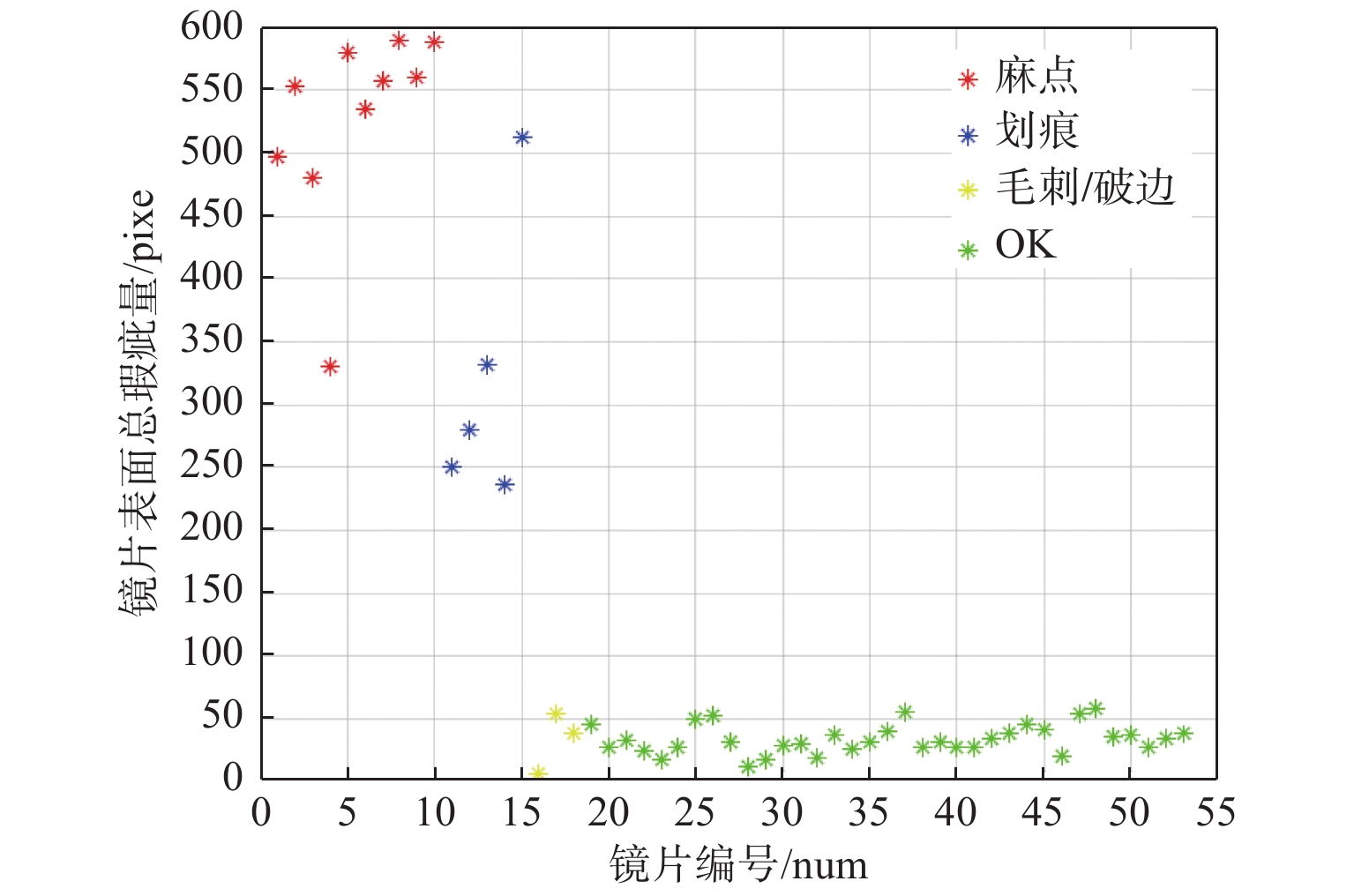

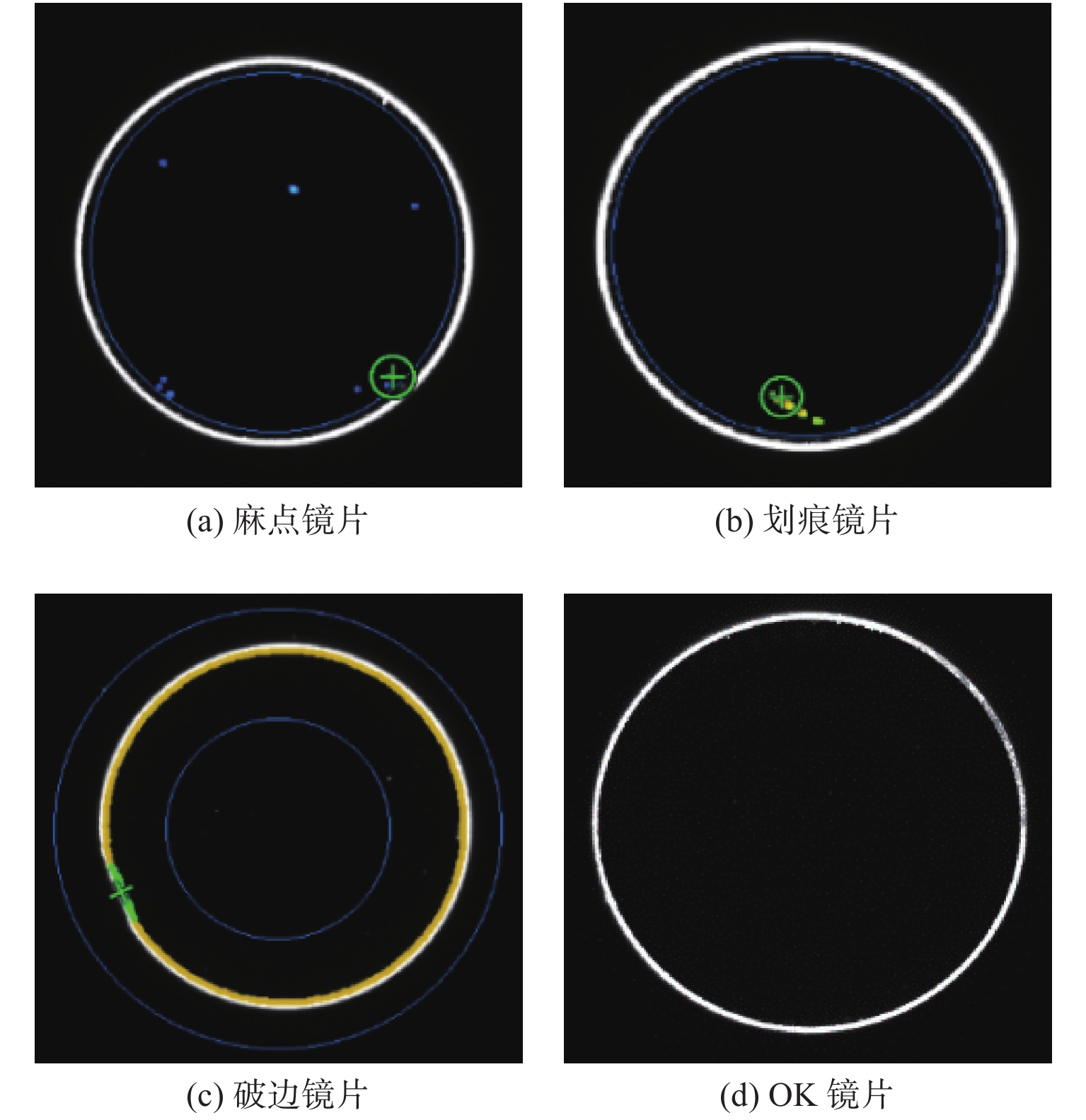

以上面检测的53块镜片的总瑕疵量(单位为pixel)为纵坐标,以镜片编号为横坐标绘制如图7所示的总瑕疵量散点图。其中镜片编号1~10为麻点镜片,镜片编号11~15为划痕镜片,镜片编号16~18为毛刺/破边镜片,镜片编号19~53为OK镜片。如图7所示,麻点镜片和划痕镜片的总瑕疵量明显比毛刺/破边镜片和OK镜片高。麻点、划痕和破边的检测图像如图8所示。

表 1 镜片瑕疵检测结果Table 1. Result of optical glasses flaws inspection瑕疵类型 麻点 划痕 破边 OK 数量(块) 10 5 3 35 表 2 镜片瑕疵检测数据Table 2. Data of optical glasses flaws inspections镜片编号 瑕疵类型 瑕疵数 总瑕疵量/pixel 最高灰度值 1 OK 0 46 61 2 0 50 52 3 0 42 45 4 麻点 — 497 77 5 — 553 172 6 — 330 104 7 划痕 — 250 50 8 — 236 32 9 — 512 207 10 毛刺/破边 1 6.5 — 11 1 54.6 — 12 1 38.6 — 由图8所示的检测图像可以清晰地看到镜片表面的麻点、划痕,破边等瑕疵。检测精度可达到1个像素(具体精度由CCD决定)。

4 结论

该检测系统利用视觉检测技术检测光学镜片表面瑕疵,在检测结构中使用了黑体来制造暗背景,取得良好的效果;在检测系统中使用了总面积瑕疵检测法来检测麻点和划痕,使用了边缘瑕疵检测法来检测毛刺和破边,检测精度可达1个像素。检测速度可达5 s/片。最后给出了基于31万像素CCD的检测结果,其中OK镜片总瑕疵量≤100 pixel,最高灰度值≤80,麻点和划痕镜片的总瑕疵量介于200 pixel~600 pixel之间,最高灰度值≤210,毛刺/破边镜片总瑕疵量≤100 pixel,最高灰度值介于200~255之间,在检测图像中能够清晰地检测出麻点、划痕和破边。并且发现麻点镜片和划痕镜片的总瑕疵量明显比毛刺/破边镜片和OK镜片高。

-

表 1 镜片瑕疵检测结果

Table 1 Result of optical glasses flaws inspection

瑕疵类型 麻点 划痕 破边 OK 数量(块) 10 5 3 35 表 2 镜片瑕疵检测数据

Table 2 Data of optical glasses flaws inspections

镜片编号 瑕疵类型 瑕疵数 总瑕疵量/pixel 最高灰度值 1 OK 0 46 61 2 0 50 52 3 0 42 45 4 麻点 — 497 77 5 — 553 172 6 — 330 104 7 划痕 — 250 50 8 — 236 32 9 — 512 207 10 毛刺/破边 1 6.5 — 11 1 54.6 — 12 1 38.6 — -

[1] 朱聪, 于广婷,李柏林, 等. 一种新的精密光学镜片表面疵病宽度测量方法[J]. 计算机应用与软件,2014,31(12):259-261, 286. doi: 10.3969/j.issn.1000-386x.2014.12.063 ZHU Cong, YU Guangting, LI Bailin, et al. A new algorithm for measuring defects width on precise optics lens surface[J]. Computer Application and Software,2014,31(12):259-261, 286. doi: 10.3969/j.issn.1000-386x.2014.12.063

[2] 朱聪. 光学镜片表面疵病检测算法研究[D]. 成都: 西南交通大学, 2014. ZHU cong. Research of the defects detection algorithm on the optical lens surface[D]. Chengdu: Southwest Jiaotong University, 2014.

[3] 陶显.基于机器视觉的大口径光学元件表面损伤检测技术研究进展[C]// 中国自动化学会控制理论专业委员会、中国系统工程学会,第三十三届中国控制会议论文集(B卷),中国自动化学会控制理论专业委员会,中国系统工程学会,中国自动化学会控制理论专业委员会,2014:1244-1249. TAO Xian. Based on machine vision of large-caliber optical element surface damage detection technology research [C].//Control theory of automation institute of professional committee of China, the systems engineering society of China. The 33rd Chinese control conference proceedings (B). The Control Theory of Automation Institute of Professional Committee of China, The Systems Engineering Society of China, 2014:1244-1249.

[4] 戴名奎, 徐德衍. 光学元件的疵病检验与研究现状[J]. 光学仪器,1996(3):32-39. DAI Mingkui, XU Deyan. Inspection and research status of optical element defects (PartⅠ)[J]. Optical Instruments,1996(3):32-39.

[5] 戴名奎, 徐德衍. 光学元件的疵病检验与研究现状(续)[J]. 光学仪器,1996(4):33-36. DAI Mingkui, XU Deyan. Inspection and research status of optical element defects (PartⅡ)[J]. Optical Instruments,1996(4):33-36.

[6] BILMES G M, ORZI D J O, MARTINEZ O E, et al. New method for realtime surface cleanliness measurement[J]. Proceedings of SPIE - The International Society for Optical Engineering,2005,5856:980-986.

[7] LORINCIK J, FINE J, GILLEN G. Scanning scattering microscope for surface and buried interface roughness and defect imaging[J]. SPIE,1997,3141:302-315. doi: 10.1117/12.279242

[8] 张翠芳, 林眉德, 王惠平. 镜片表面瑕疵自动化检测趋势展望[J]. 中国眼镜科技杂志,2015(9):133-134. doi: 10.3969/j.issn.1004-6615.2015.09.046 ZHANG Cuifang, LIU Meide, WANG Huiping. Prospect of automatic detection of lens surface defects[J]. China Glasses Science-Technology Magazine,2015(9):133-134. doi: 10.3969/j.issn.1004-6615.2015.09.046

[9] 姚红兵, 曾祥波, 马桂殿, 等. 镜片疵病视觉在线检测方法[J]. 激光与光电子学进展,2013,50(12):77-82. YAO Hongbing, ZENG Xiangbo, MA Guidian, et al. The method for online visual detection of lens defects[J]. Laser and Optoelectronics Progress,2013,50(12):77-82.

[10] ZHANG Yihui, YANG Yongying, LI Chen, et al. Defects evaluation system for spherical optical surfaces based on microscopic scattering dark-field imaging method[J]. Applied Optics,2016,55(23):6162-6171. doi: 10.1364/AO.55.006162

[11] LI Chen, YANG Yongying, CHAI Huiting, et al. Dark-field detection method of shallow scratches on the super-smooth optical surface based on the technology of adaptive smoothing and morphological differencing[J]. Chinese Optics Letters,2017(8):57-61.

[12] HE Z, SUN L. Surface defect detection method for glass substrate using improved Otsu segmentation[J]. Applied Optics,2015,54(33):9823. doi: 10.1364/AO.54.009823

[13] 赵朋, 颉俊, 傅建中, 等. 塑料光学透镜的磁悬浮检测[J]. 光学精密工程,2016,24(4):756-763. doi: 10.3788/OPE.20162404.0756 ZHAO Peng, JIE Jun, FU Jianzhong. Magnetic levitation detection for plastic optical lenses[J]. Optics Precision Engineering,2016,24(4):756-763. doi: 10.3788/OPE.20162404.0756

[14] 颉俊. 磁悬浮检测技术的理论分析及应用研究[D]. 杭州: 浙江大学, 2017. JIE Jun. Theoretical analyses of magnetic levitation detecting technique and its applications[D]. Hangzhou: Zhejiang University, 2017.

[15] 全国光学和光子学标准化技术委员会.GB/T 1185-2006光学零件表面疵病[S]. 北京: 中国标准出版社, 2007. National Technical Committee of Standardization of Optics and Photonics. GB/T 1185-2006 optical parts surface defects[S]. Beijing: China Standard Press, 2007.

[16] 阮友德. 任务引领型PLC应用技术教程. 上册[M]. 北京: 机械工业出版社, 2013.9: 133-136. RUAN Youde. Task-oriented PLC application technology tutorial(Volume One)[M]. Beijing: China Machine Press, 2013: 133-136.

[17] 向晓汉. 三菱FX系列PLC完全精通教程[M]. 北京: 化学工业出版社, 2012: 126-132. XIANG Xiaohan. Mitsubishi FX series PLC full proficiency tutorial[M]. Beijing: Chemical Industry Press, 2012: 126-132.

-

期刊类型引用(5)

1. 陈军,王青,周辉阳. 装配式工程易变形结构裂缝红外微弱目标识别方法. 粉煤灰综合利用. 2023(04): 122-127 .  百度学术

百度学术

2. 赵琳. 基于视觉数据融合和机器学习算法的在役桥梁病害智能检测方法. 计算技术与自动化. 2023(04): 47-52 .  百度学术

百度学术

3. 刘宏伟,沈世鑫,李威翰. 基于激光全息技术的桥梁基桩受载力应变规律研究. 激光杂志. 2022(02): 173-177 .  百度学术

百度学术

4. 邹易清,苏建功,夏晓华,李玉强,蒋立军,韦耀淋. 基于改进YOLO V4的桥梁缆索表面损伤识别方法. 电子设计工程. 2022(10): 172-176+182 .  百度学术

百度学术

5. 徐欣,苏梦婷,陈彦,操卫康,张军. 基于图像识别的电力电缆隧道结构病害检测. 自动化技术与应用. 2022(11): 23-26 .  百度学术

百度学术

其他类型引用(1)

下载:

下载:

陕公网安备 61011302001501号

陕公网安备 61011302001501号