Three dimensional micro surface measurement system based on stereomicroscope

-

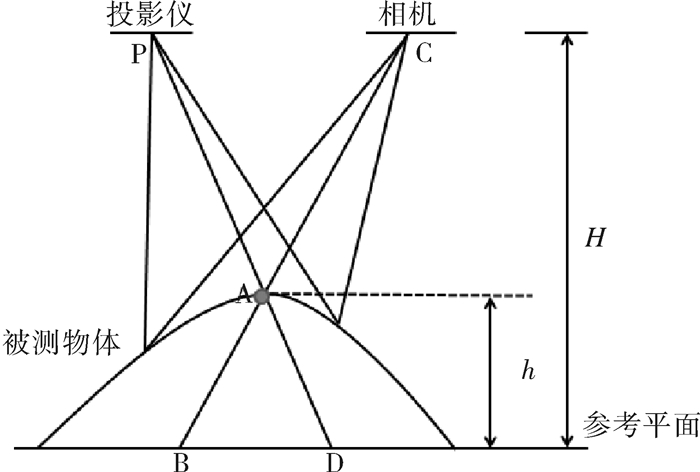

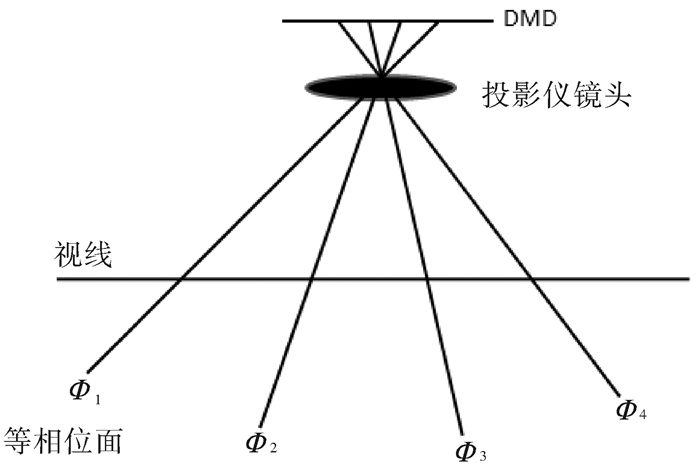

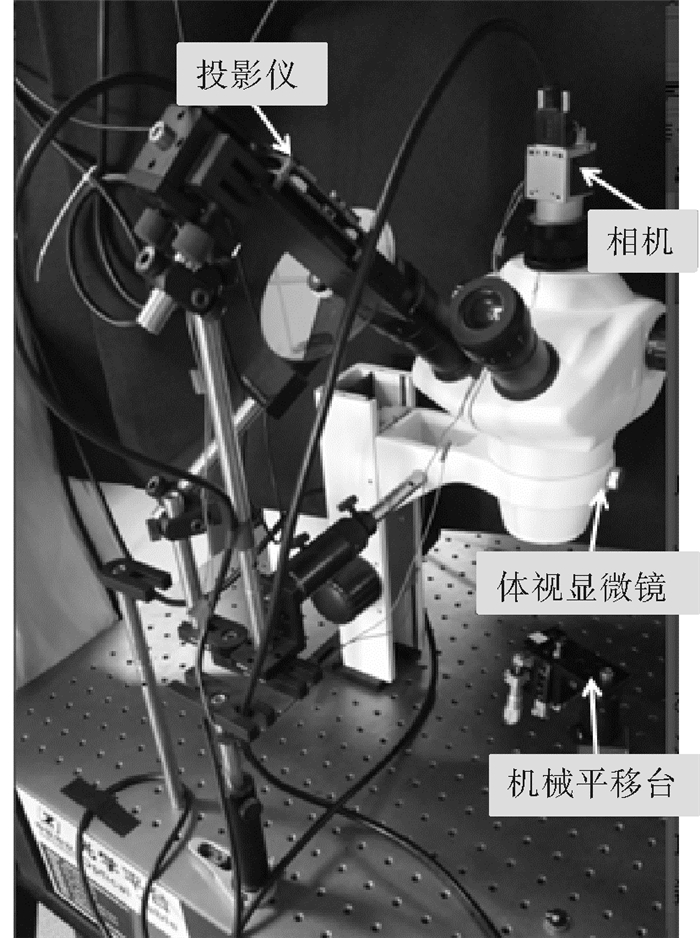

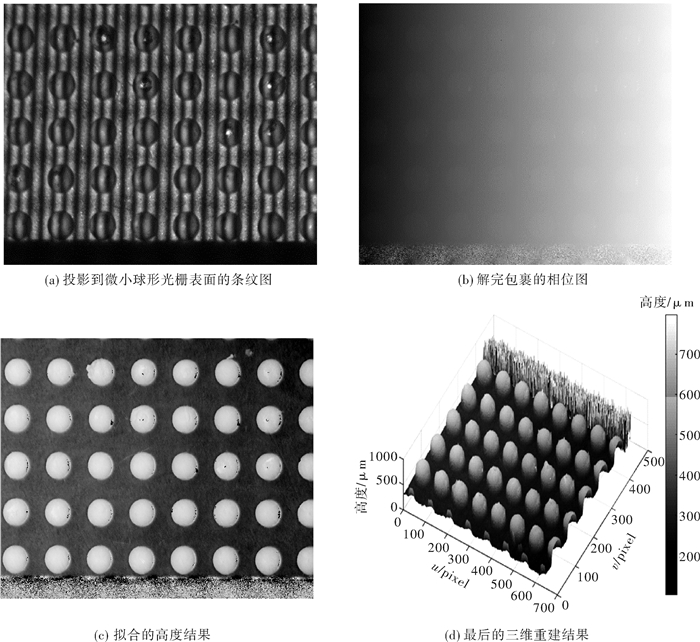

摘要: 将条纹投影轮廓测量术和体视显微镜相结合,搭建了一套能够对微小器件的表面三维形貌进行测量的系统。该系统由一台Greenough型的体视显微镜,一台DMD投影仪,一个CCD相机和一个机械平移台组成。在利用相移算法和降级去包裹算法得到被表面形貌调制过的无歧义相位后,通过相位和高度的映射关系,得到高度值,从而能够对微小器件的表面形貌进行重建。在标定时,通过精密的机械平移台将陶瓷标定板置于不同的高度,对其进行相位测量,得到多组相对应的相位和高度值,再对每个像素点进行多项式拟合来确定相位和高度的映射关系。实验测量了标定的最后一个平面以及微型的球栅阵列,平面测量结果显示测量误差在10 μm以内,从微型球栅阵列的三维重建结果可以清晰地看到排列的球形结构。实验结果证明了该系统对于平面和复杂的三维结构都能够进行精确的测量。Abstract: Combining fringe projection profilometry and stereomicroscope, a system is setup which can measure three-dimensional topography of micro devices. This system consists of Greenough-type stereomicroscope, projector, CCD camera and mechanical translation table. After unambiguous phase is obtained by using phase shift algorithm and descrambling method, which is modulated by surface topography, height value is obtained by phase and height mapping relationship, so that surface morphology of micro devices can be reconstructed. At the time of calibration, ceramic calibration plate is set at different heights by means of a precision mechanical translation table, and several groups of corresponding phase and height values are obtained. Then polynomial fitting of each pixel is performed to determine phase-height mapping. Last calibrated plane and micro ball grid array are measured. Results show that measurement error is within 10μm, and spherical structure is clearly seen from three-dimensional reconstruction of micro-ball grid array. It is proved that system can accurately measure both planar and complex three-dimensional structures.

-

引言

太阳模拟器作为一种重要的试验与测试设备被广泛应用于航天领域和太阳能利用领域,目前国内外对太阳模拟器均进行了相关研究[1-5]。太阳模拟器光源主要分为氙灯和LED 2种,氙灯虽然具有高亮度、光谱分布接近太阳光谱等优点[6-7],但是由于受到氙灯自身特性的限制,光电转换效率低、稳定性差、寿命短[8],使得太阳模拟器的生产成本和维修费用居高不下。而LED则具有高效节能、清洁环保、寿命长、可控性强以及光谱匹配技术较成熟[9-11]等优点,因此已逐步应用于对新型太阳模拟器的研发中,目前LED太阳模拟器的研究已经成为太阳模拟器研究领域的主流。2003年,日本东京农业大学Kohraku S[12]等人发布了LED太阳模拟器的研究成果,该仪器选用了4种中心波长的LED进行相关光谱响应测试和LED特性测试,最后获得了边长为10 cm的辐照面,辐照强度可达到420 W/m2。美国Newport公司研发出新型LED太阳模拟器LSH-7520,利用400 nm~1 100 nm范围内的19种不同中心波长的LED组成太阳模拟器光源模块,最终获得辐射光斑尺寸为51 mm×51 mm,辐照稳定性达到A级标准。2008年,Tsuno[13]等人利用2 304颗LED研制了一种辐照面为100 mm×100 mm的LED太阳模拟器,其光源尺寸为335 mm×335 mm。近年来,国内也对LED太阳模拟器进行了相关研究。李果华[14]等人利用光学混合模块发明了一种新型LED太阳模拟器,辐照强度达到1 000 W/m2。台湾仪测科技国际集团推出一种新型的辐照强度连续可调的LED太阳模拟器WSLED-100SC,最终实现光谱范围365 nm~1 070 nm、光谱匹配度优于±25%、辐照不均匀度优于±10%、辐照不稳定度优于±1%,在工作距离为40 mm处的有效辐照面积100 mm×100 mm区域内辐照强度达到600 W/m2。

根据上述分析可知,目前的LED太阳模拟器能够有效地解决氙灯太阳模拟器光谱调制手段不足的缺陷,但是其辐照强度与均匀性同时达到较好的指标还是存在一定困难的。因此,本文从提高LED太阳模拟器输出的辐射强度和辐照面积均匀性入手,提出了一种高辐照强度高均匀性的LED太阳模拟器光学系统的设计方法,结合LED阵列光源技术、光学积分器匀光技术和准直光学系统技术完成LED太阳模拟器光学系统的设计,并利用建模仿真技术与实验对设计结果进行验证。

1 光学系统设计

1.1 原理

LED太阳模拟器光学系统主要由光源系统、匀光系统、以及准直光学系统构成,系统框图如图 1所示。光源系统由多种不同中心波段的LED矩形阵列分布在球面上,提供充足的光通量。匀光系统采用光学积分器组件将光源光线进行分割和叠加形成均匀的辐照空间分布。准直光学系统采用双分离结构将匀光系统出射的光线进行准直,最后在辐照面上形成均匀的辐照光斑。

1.2 准直光学系统设计

根据LED太阳模拟器对高辐照强度和高均匀性的照明的要求,本文采用同轴透射式准直光学系统[15],同时考虑到太阳模拟器光学系统准直口径和准直角[16]等因素,选取双分离透镜作为光学系统的准直结构,双分离透镜不仅能有效地提高LED太阳模拟器的光能利用率,而且可以通过对双分离透镜结构参数的优化来提高系统的准直性[17]。

准直光学系统的物像关系如图 2所示。

各参数之间满足关系式:

$$ {D_1} \ge D + L \times \tan \theta $$ (1) 式中:D1为准直系统有效通光口径;D为有效辐照面外切圆直径;L为辐照面工作距离;θ为准直半角。

根据LED太阳模拟器设计指标,光学系统的工作距离为100 mm,准直半角为1.5°,辐照面积大小为100 mm×100 mm(辐照面外接圆直径为142 mm)。因此可知准直物镜通光口径应大于144.62 mm。同时为了保证辐照面的有效口径的尺寸,故将准直物镜的通光孔径选为160 mm。选取光学系统相对孔径为1/4[17], 则透镜的焦距为640 mm。透镜材料选用高透过率的冕牌火石光学玻璃即K9(正透镜)、ZF1(负透镜)。准直光学系统透镜参数如表 1所示,光路如图 3所示。

表 1 双分离透镜参数表Table 1. Parameters of double-separation lens曲率半径/mm 厚度/mm 玻璃 直径/mm 正透镜 344.293 32 K9 160 -273.810 6.312 160 负透镜 -264.602 15 ZF1 160 -1094.178 160 1.3 匀光系统设计

匀光系统通常分为积分器[18]和匀光棒[19]2种,前者设计、加工复杂,但是匀光性能好;后者结构简单,但对与之匹配的聚光系统的性能要求较高,否则匀光效果不佳。因此选择积分器作为光学系统的匀光系统。

光学积分器由两组参数完全相同的多个透镜按中心对称的方式排列成透镜阵列组成,分别称为场镜组和投影镜组。场镜组和投影镜组分别位于相互的焦点处,其中场镜组中每一个单元透镜分别与投影镜组中所对应单元透镜同光轴。积分器原理图如图 4所示。

为了使光束充满整个光阑,积分器的有效通光口径应大于视场光阑的口径,同时为了留出机械加工余量,因此,将积分器的有效通光口径取为40 mm。积分器式匀光系统的每个阵列透镜称为一个通道,单位面积上通道越多,理论上其匀光效果越好。但是在积分器式匀光系统通光口径一定的情况下,通道数越多,阵列透镜的口径越小,其成像倍率也就越大,对阵列透镜加工与排列时的定位精度的要求也更高,积分器式匀光系统的结构也将变得复杂[20]。为了方便积分器式匀光系统匀光需要进行“边缘补偿”,积分器式匀光系统通道的形状以六边形和正方形为主。其中六边形通道匀光效果更均匀,光能利用率也更高。因此选用光学通道数为19的正六边形透镜[21]的积分器。积分器透镜内切圆半径α1与有效通光口径D3关系为

$$ {\left( {5{\alpha _1}} \right)^2} + {\left( {\frac{{\sqrt 3 }}{3}{\alpha _1}} \right)^2} = {\left( {\frac{{{D_3}}}{2}} \right)^2} $$ (2) 因此正六边形透镜元素的内切圆直径为7.94 mm, 取透镜的相对孔径为1/4, 得出每个透镜的焦距为31.77 mm, 透镜选为平凸透镜, 这样便于放置在基板上。同时积分器式匀光系统的光焦度可以表示为

$$ \varphi = \left( {n - 1} \right)\left( {\frac{1}{{{r_1}}} - \frac{1}{{{r_2}}}} \right) $$ (3) 式中:n为积分器式匀光系统的折射率,积分器式匀光系统的材料多为有机玻璃,因此折射率n为1.49;r1为积分器式匀光系统的曲面半径;r2为积分器式匀光系统的平面半径;φ为透镜的光焦度。因此r2=∞。积分器式匀光系统的曲面半径可以表示为

$$ {r_1} = \frac{{n - 1}}{\varphi } = 15.57{\rm{mm}} $$ (4) 为了满足辐照面为正方形视场的要求,需要在积分器后边加入视场光阑,视场光阑可以起到拦截影响辐照均匀性的部分杂散光与约束光学系统的准直角的作用。视场光阑原理如图 5所示。

视场光阑外切圆直径D2与准直角θ,以及准直物镜的焦距f的关系式如下:

$$ {\rm{tan}}\theta {\rm{ = }}\frac{{{D_2}}}{{2f}} $$ (5) 由(5)式可知,D2=Φ33.5 mm。因此视场光阑正方形开口尺寸为23.68 mm×23.68 mm。

由于光学积分器与视场光阑距离很近, 所以光学积分器处会聚了很高的能量, 为了防止光阑因高温而变形, 应选择热膨胀系数较低的铝合金材料2A12。

1.4 光源系统设计

1.4.1 光源发散角分析

LED的发散角大小是影响辐照光斑均匀性的一个重要因素。若LED的发散角选取过大,球面阵列光源与积分器的距离减小,导致球面阵列LED光源能量损失,结合目前现有LED的发散角(一般为120°),其配光曲线如图 6所示。因此利用二次光学设计方法对LED的发散角进行准直化处理。目前LED的二次光学设计可达到2.4°[15]。选取9个LED灯,通过对不同发散角(2.5°~3.5°)对光学系统辐照均匀性的影响进行分析,结果如图 7所示。在发散角小于3.2°时辐照均匀性逐渐变好。在超过3.2°时辐照均匀性变差。因此综合考虑选取3°作为LED的发散角进行仿真分析。

1.4.2 LED阵列光源设计

针对目前普遍应用的平面LED阵列光源[22-23],本文提出一种球面LED阵列光源的布置方法,有效地简化了光学系统结构,球面阵列光源工作光路如图 8所示。

因此,积分器有效通光孔径D3与LED的发散角θ1、以及球面半径R的关系如下:

$$ R = \frac{{{D_3}}}{{2\tan \frac{{{\theta _1}}}{2}}} $$ (6) 本文设计的球面阵列光源是由6种不同波段225个功率为3 W的LED均匀分布在球面上构成的,根据(6)式可知,此时球面半径R=763.77 mm。为了避免LED之间相互干涉,将每个LED之间的距离取为15.8 mm,此时球面的径向尺寸为340 mm。为了减小球面加工误差,LED安装方便,在LED安装位置上加工Φ9×1 mm的安装凹槽,球面阵列光源的结构如图 9所示。

2 光学系统仿真分析

太阳模拟器辐照均匀性是太阳模拟器的重要指标之一,因此需要对太阳模拟器进行仿真验算。根据以上各部分设计尺寸以及各透镜材料属性建立相应的光学系统模型,并利用LightTools进行光学系统仿真验算。各透镜材料属性如表 2所示,LED太阳模拟器光线追迹结果如图 10所示。

表 2 透镜材料属性表Table 2. Properties of lens material透镜 反射率 透射率 吸收率 材料 场镜 0.06 0.91 0.03 JGS3 投影镜 0.06 0.91 0.03 JGS3 准直镜 0.01 0.98 0.01 K9 0.01 0.98 0.01 ZF1 LED阵列光源发出的光线经过光学系统各个元件,最后在辐照面形成辐照光斑,通过统计落在辐照平面上不同小区域内的光线数目来确定照度的分布情况。辐照面面积为100 mm×100 mm, 划分成10×10个网格,追迹光线为25万,光学系统仿真结果如图 11所示。辐照面内不均匀性为3.6%,说明太阳模拟器设计合理。

3 实验验证

本文采用北京师范大学研制的光学辐照计对LED太阳模拟器进行光学性能检测,通过对辐照强度和辐照均匀性的实验数据进行分析,进一步验证LED太阳模拟器光学系统仿真的真实性与合理性。

3.1 辐照强度测试

打开LED太阳模拟器的电源开关,将其功率调至最大,待工作稳定后,将光学辐照计放置于辐照面中心处进行辐照强度测试,为了更好地实现测试的准确性,测试过程中采用多次测量取平均值的方法。结果表明在400 nm~1 100 nm的波段范围内辐照面上的积分辐照强度为1 105 W/m2。

3.2 辐照均匀性测试

辐照面上测试点数量的选取和测试器件窗口面积的选择是影响LED太阳模拟器辐照均匀性的2个重要因素。根据我国太阳模拟器辐照均匀性的测试原则,要求将测试的辐照面分成不少于36等分,测试器件窗口面积应选择独立等分面积的25%以上。按照这个原则,在实际测试过程中,将辐照计垂直于光轴固定在二维电动调整台上,使其在120 mm×120 mm的辐照面上沿X轴和Y轴平移运动,步长为10 mm,扫描测试辐照面内各点的辐照强度如图 12所示。

开启LED太阳模拟器电源开关,将辐照强度调至500 W/m2,同时打开二维电动调整台,待其工作稳定后,根据辐照面不均匀测试方法对辐照面进行扫描测量。

辐照面不均匀度计算公式如下:

$$ Nu = \frac{{{E_{\max }} - {E_{\min }}}}{{{E_{\max }} + {E_{\min }}}} \times 100\% $$ (7) 式中:Nu辐照不均匀度;Emax为辐照面的最大辐照强度;Emin为辐照面的最小辐照强度。

实验结果表明:在辐照面100 mm×100 mm的范围内,LED太阳模拟器辐照不均匀度优于3.86%,与仿真结果基本保持一致。在实际测量过程中,影响测量不均匀度的因素包括:LED阵列光源的稳定性,探测器的稳定性,探测器的非线性以及其他因素等,详细情况如表 3所示。LED阵列光源稳定性根据测量面均匀时探测器同步监视光源的输出值给出,其不确定度优于1.5%;根据探测器的实验室定标检测报告,探测器稳定性的不确定度为0.8%,探测器非线性的不确定度为0.2%;考虑到环境的杂散光、系统装调误差等其他因素,通过多次重复测量,其不确定度可优于0.3%。基于以上分析,在置信水平95%(k=2)的情况下,辐照面不均匀性测量的合成相对不确定度为1.2%。

表 3 测量的不确定度Table 3. Uncertainty of measurement光源 不确定度/%(k=2) 光源稳定性 1.5 探测器稳定性 0.8 探测器非线性 0.2 其他不确定度 0.3 合成相对不确定度 1.2 4 结论

根据LED太阳模拟器对高辐照强度和高均匀性的要求,提出一种LED太阳模拟器光学系统的设计方法,分析了LED太阳模拟器光学系统的组成和工作原理,着重优化设计了准直光学系统、匀光系统以及光源系统,利用LightTools软件对LED太阳模拟器光学系统进行仿真。通过实验验证实际测试结果与仿真结果相一致:在工作距离为100 mm, 辐照面积为100 mm×100 mm范围内, 太阳模拟器辐照强度高于1 100 W/m2,辐照均匀性优于3.86%。

-

-

[1] Zhang Q, Su X. High-speed optical measurement for the drumhead vibration[J]. Optics Express, 2005, 13(8): 3110-3116. doi: 10.1364/OPEX.13.003110

[2] 朱统晶, 周平, 刘欣冉, 等.结构光三维测量系统标定的关键算法研究[J].应用光学, 2014, 35(5): 848-852. http://d.old.wanfangdata.com.cn/Periodical/yygx201405022 Zhu Tong-jing, Zhou Ping, Liu Xinran, et al.Crucial algorithms for structural light 3D measurement system calibration[J].Journal of Applied Optics, 2014, 35(5): 848-852. http://d.old.wanfangdata.com.cn/Periodical/yygx201405022

[3] Zuo C, Chen Q, Gu G, et al. High-speed three-dimensional shape measurement for dynamic scenes using bi-frequency tripolar pulse-width-modulation fringe projection[J]. Optics and Lasers in Engineering, 2013, 51(8): 953-960. doi: 10.1016/j.optlaseng.2013.02.012

[4] 王露阳, 达飞鹏.基于彩色光栅投影的快速三维测量方法[J].应用光学, 2011, 32(2): 276-281. doi: 10.3969/j.issn.1002-2082.2011.02.018 Wang Luyang, Da Feipeng.Rapid 3D shape measurement based on color-encoded fringe projection[J].Journal of Applied Optics, 2011, 32(2): 276-281. doi: 10.3969/j.issn.1002-2082.2011.02.018

[5] Zhang S. Recent progresses on real-time 3D shape measurement using digital fringe projection techniques[J]. Optics and Lasers in Engineering, 2010, 48(2): 149-158. doi: 10.1016/j.optlaseng.2009.03.008

[6] Schreier H W, Garcia D, Sutton M A. Advances in light microscope stereo vision[J]. Experimental Mechanics, 2004, 44(3): 278-288. doi: 10.1007/BF02427894

[7] Chen Z, Liao H, Zhang X. Telecentric stereo micro-vision system: Calibration method and experiments[J]. Optics and Lasers in Engineering, 2014, 57(6): 82-92. http://d.old.wanfangdata.com.cn/NSTLQK/NSTL_QKJJ0232414923/

[8] Yin Y, Wang M, Gao B Z, et al. Fringe projection 3D microscopy with the general imaging model[J]. Optics Express, 2015, 23(5): 6846-6857. doi: 10.1364/OE.23.006846

[9] Li A, Peng X, Yin Y, et al. Fringe projection based quantitative 3D microscopy[J]. Optik-International Journal for Light and Electron Optics, 2013, 124(21): 5052-5056. doi: 10.1016/j.ijleo.2013.03.070

[10] Zhang C, Huang P S, Chiang F P. Microscopic phase-shifting profilometry based on digital micromirror device technology[J]. Applied Optics, 2002, 41(28): 5896-5904. doi: 10.1364/AO.41.005896

[11] Kim E H, Hahn J, Kim H, et al. Profilometry without phase unwrapping using multi-frequency and four-step phase-shift sinusoidal fringe projection[J]. Optics Express, 2009, 17(10): 7818-7830. doi: 10.1364/OE.17.007818

[12] Liu H, Su W H, Reichard K, et al. Calibration-based phase-shifting projected fringe profilometry for accurate absolute 3D surface profile measurement[J]. Optics Communications, 2003, 216(1): 65-80. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=13302ce325b11f80c5dfc9082a93f106

-

期刊类型引用(2)

1. 郑国权, 唐悦, 刘宣. 基于光纤技术的电能信息采集系统设计. 激光杂志. 2020(05): 173-177 .  百度学术

百度学术

2. 赵俊成, 刘建平. 多光电侦察设备综合网络体系方案研究. 应用光学. 2019(06): 1015-1021 .  本站查看

本站查看

其他类型引用(0)

下载:

下载:

陕公网安备 61011302001501号

陕公网安备 61011302001501号